These 3D printed objects immediately revert to original position after modification

With the help of some light, engineers from MIT and Singapore University of Technology and Design (SUTD) have figured out a way to 3D print structures that can recall and revert back to their original shapes. After being stretched, twisted, and bent at extreme angles, the structures, which ranged from small coils to an inch-tall replica of the Eiffel tower, were able to change their shape into the original form within seconds of being heated to a predetermined temperature “sweet spot.”

The new heat-responsive materials could potentially assist in controlled drug delivery and solar panel tracking.

“We ultimately want to use body temperature as a trigger,” said Nicholas X. Fang, associate professor of mechanical engineering at MIT. “If we can design these polymers properly, we may be able to form a drug delivery device that will only release medicine at the sign of a fever.”

According to former MIT-SUTD research fellow Qi “Kevin” Ge, 3D printing shape-memory materials can also be considered a form of 4D printing, since the structures are designed to change over the fourth dimension — time.

“Our method not only enables 4-D printing at the micron-scale, but also suggests recipes to print shape-memory polymers that can be stretched 10 times larger than those printed by commercial 3-D printers,” said Ge. “This will advance 4-D printing into a wide variety of practical applications, including biomedical devices, deployable aerospace structures, and shape-changing photovoltaic solar cells.”

The team has been looking to different varieties of soft and active materials that could be new tools. These new materials, including shape-memory polymers, have the ability to stretch and deform dramatically in response to environmental stimuli such as heat, light, and electricity, which can all help researchers in the biomedical field to create soft robots, wearable sensors, and artificial muscles.

Shape-memory polymers can switch between two states: a harder, low-temperature, amorphous state, and a soft, high-temperature, rubbery state. The bent and stretched shapes can be stuck at room temperature, but then can snap back to their original form under heated conditions.

In order to create shape-memory structures, some researchers have employed 3D printing since the technology allows them to custom-design structures with fine detail. The only issue with this method is that conventional 3D printers only allow for the design of structures with details no smaller than a few millimeters, placing a size restriction on the material. The researchers say that this can limit how fast the material can recover its original shape.

“The reality is that, if you’re able to make it to much smaller dimensions, these materials can actually respond very quickly, within seconds,” said Fang. “For example, a flower can release pollen in milliseconds. It can only do that because its actuation mechanisms are at the micron scale.”

In order to achieve shape-memory structures with finer details, Fang and the team tested a unique 3D printing process called microstereolithography, which uses light from a projector to print patterns on successive layers of resin.

“We’re printing with light, layer by layer,” said Fang. “It’s almost like how dentists form replicas of teeth and fill cavities, except that we’re doing it with high-resolution lenses that come from the semiconductor industry, which give us intricate parts, with dimensions comparable to the diameter of a human hair.”

The light-printed material can reshape back to its original printed form within a specific temperature range, which in this case is between 104º to 356º F.

Fang also discovered that the structures could be stretched up to three times their original length without breaking. Though they can bounce back to their original shape in just seconds, Fang looks to even push response time to milliseconds.

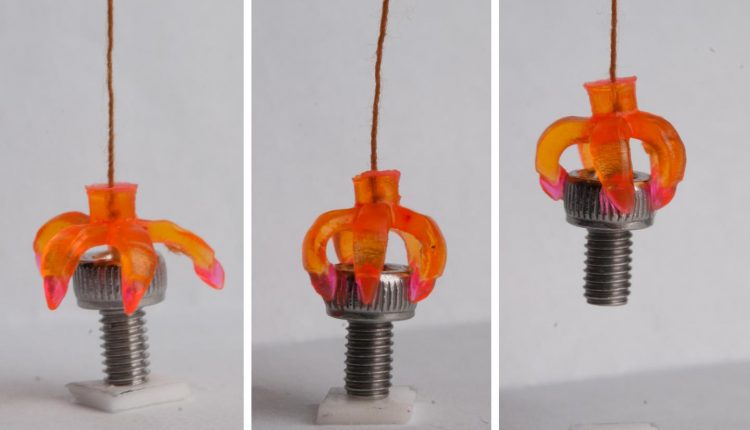

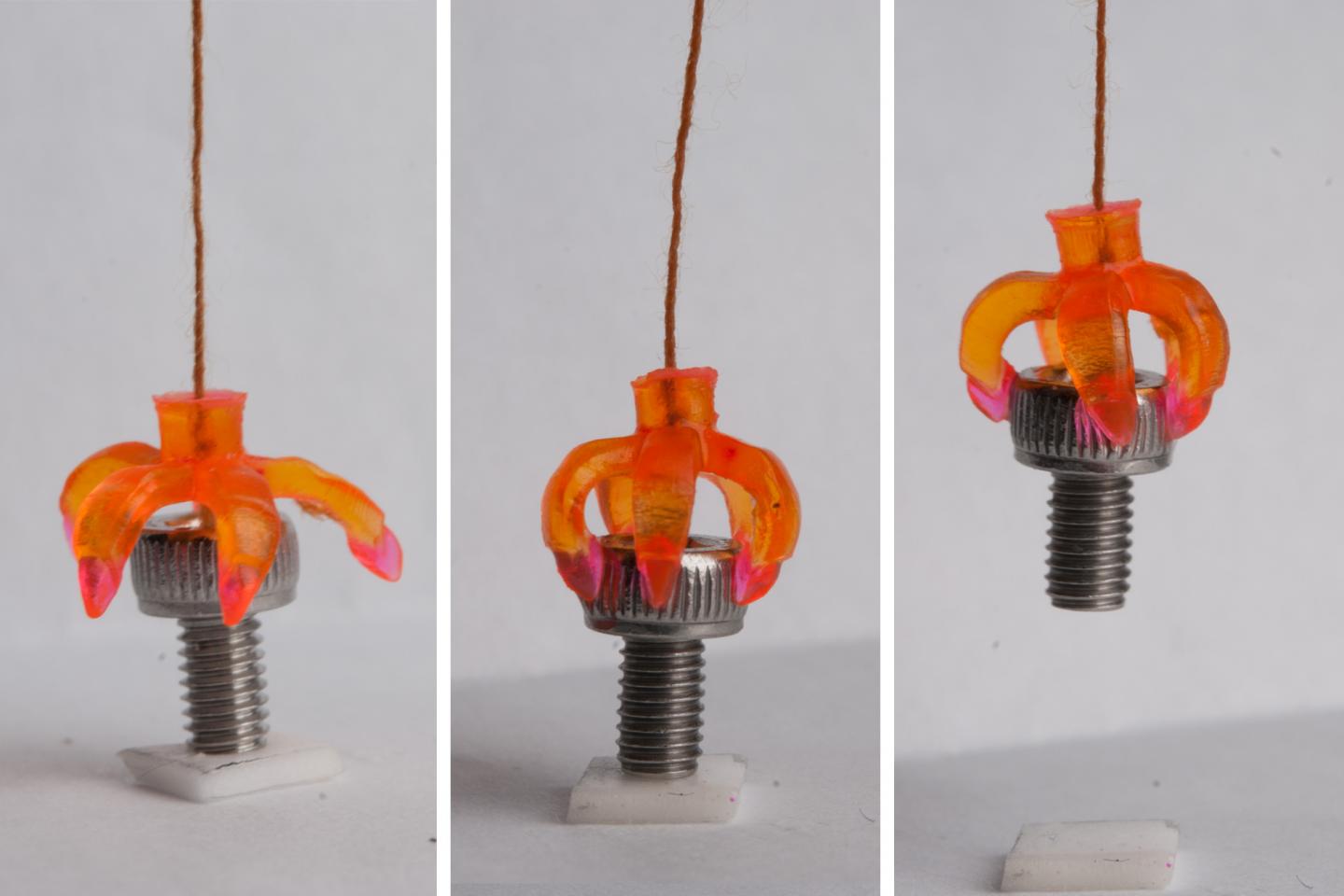

To demonstrate the technology and its potential applications, the team printed a small rubber claw gripper and attached a thin handle to the base of the gripper. They then stretched the gripper’s claws open, but once under the heat, the gripper was able to close and capture whatever object was placed below it.

“The grippers are a nice example of how manipulation can be done with soft materials,” said Fang. “We showed that it is possible to pick up a small bolt, and also even fish eggs and soft tofu. That type of soft grip is probably very unique and beneficial.”

In the future, the team would like to find combinations of polymers to make shape-memory materials that react to lower temperatures, ones within the range of human body temperatures, for use in soft, active, controllable drug delivery capsules.

Comments are closed, but trackbacks and pingbacks are open.