5 ways 3D printing will be used in bioengineering

3D-printing technology is being used in a variety of applications, ranging from food, to houses, to prosthetic limbs. Now that the technology has advanced so rapidly, bioengineers are looking to implement 3D printing into the manufacturing actual cellular material. Doing so could lead to future biomedical devices, tissue-engineered skin, cartilage, and bone — even functional organs. Take a look at these five future possibilities for 3D bioprinting, which, according to researchers we can see come to fruition in the next few years.

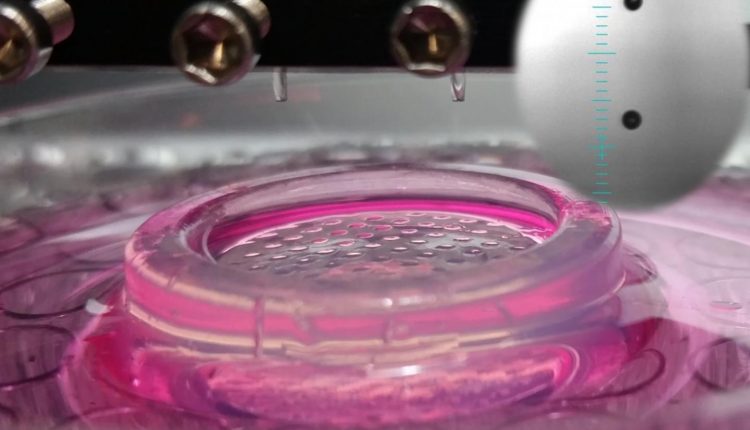

1. Organs-on-a-Chip

According to the research, “organs-on-a-chip,” 3D-printed systems that mimic the structure and function of human tissue are in the works to deliver medicine in a less expensive and efficient manner. To date, lung, gut, and pancreatic tissue have already been grown from human stem cells on the chips. While researchers will still have to overcome manufacturing challenges, 3D printing could reduce the labor and costs necessary to build, seed, and meet the demand for chips.

“The intersection of 3D printing for microfluidic fabrication and bioprinting 3D tissues shows great promise in the direction of single-step organ-on-a-chip engineering and can allow greater flexibility and throughput in the research process,” said Savas Tasoglu, assistant professor at the University of Connecticut, who works on developing new applications of 3D printing in microfluidics and organs-on-a-chip.

The researchers envision a future of advanced 3D bioprinters capable of printing a range of materials to simplify the creation of organ-on-a-chip models.

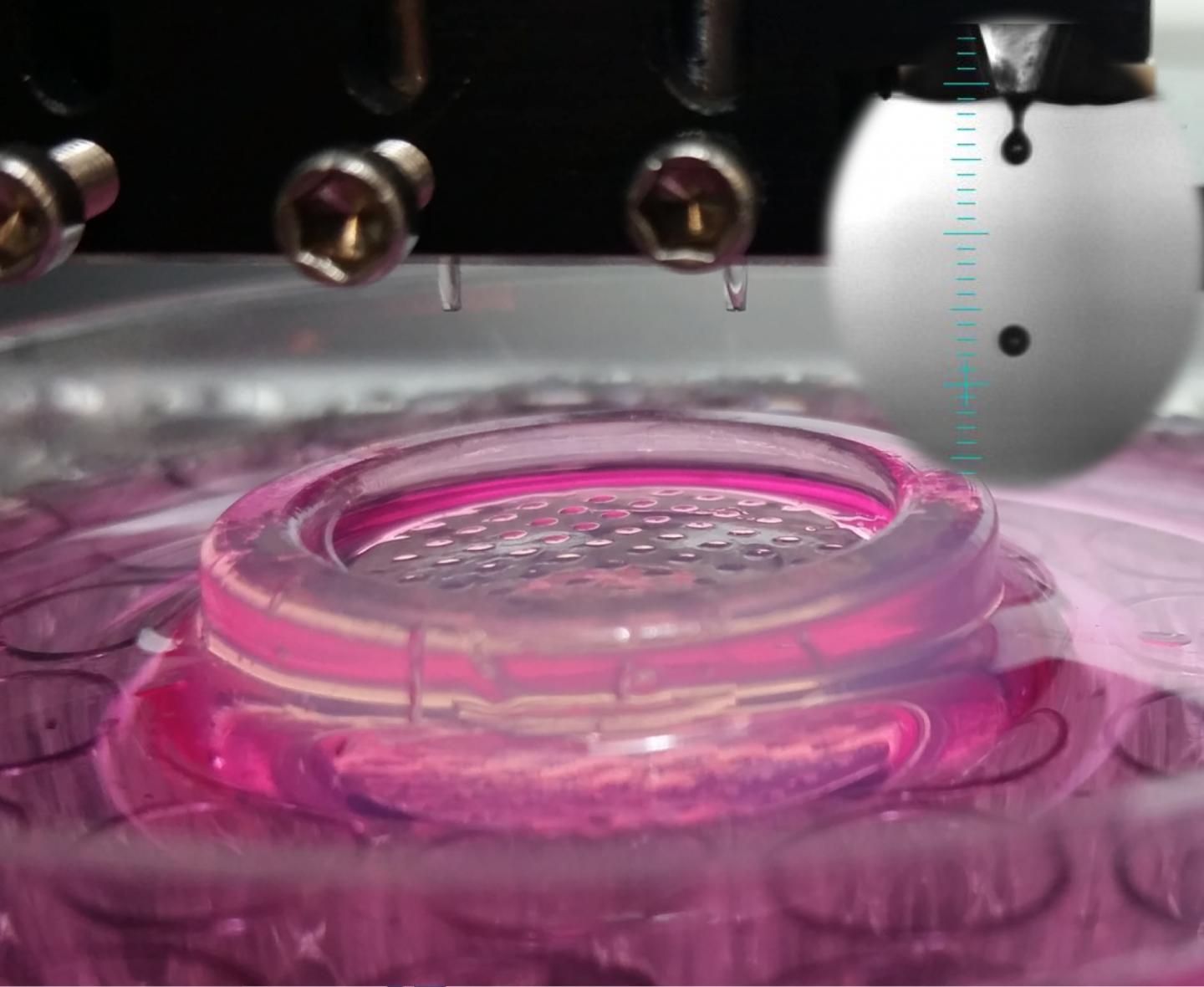

2. Skin Manufacturing

Another future possibility is printed skin made from cells set down on a collagen gel. In studies, the gel has shown the presence of intercellular connections and biologically normal cell markers 10 days after cultivation. Other researchers have been able to grow blood vessels in this sheet of cells.

According to the research, skin bioprinting is closer to reality than we know, and could be designed to help patients with burns or chronic wounds.

“It is now a reality to utilize sophisticated machine control to create tissue-engineered constructs,” said Wei Long Ng and fellow researchers from the Nanyang Technological University and the Agency for Science, Technology, and Research in Singapore. “Although the ultimate goal of bioprinting a skin equivalent with complete functional performance has yet to be achieved, bioprinting shows promises in several critical aspects of skin tissue engineering, including creating pigmented and/or aging skin models, vasculature networks, and hair follicles.”

3. Facial Reconstruction

So far, bone, cartilage, skin, muscle, blood vessels, and nerves have all been printed in a lab, so now researchers are working to create more complex designs that can be implated in patients. Craniofascial reconstruction would be benefit people with cancer or those who have experienced facial injuries,.

A more short-term use of the technology in this applications is 3D-printed scaffolds which could be used to improve defects in the jaw or other areas of the face.

“With the need for long-term (pre)clinical studies, intelligent polymers, and ultimately good manufacturing production of bioprinted constructs, there is still a long road ahead,” said Dafydd Visscher, surgeon physician, and colleagues at the VU University Medical Center in Amsterdam.

The researchers envision a handheld bioprinting device that could allow for cells to be delivered into tissues like skin or cartilage.

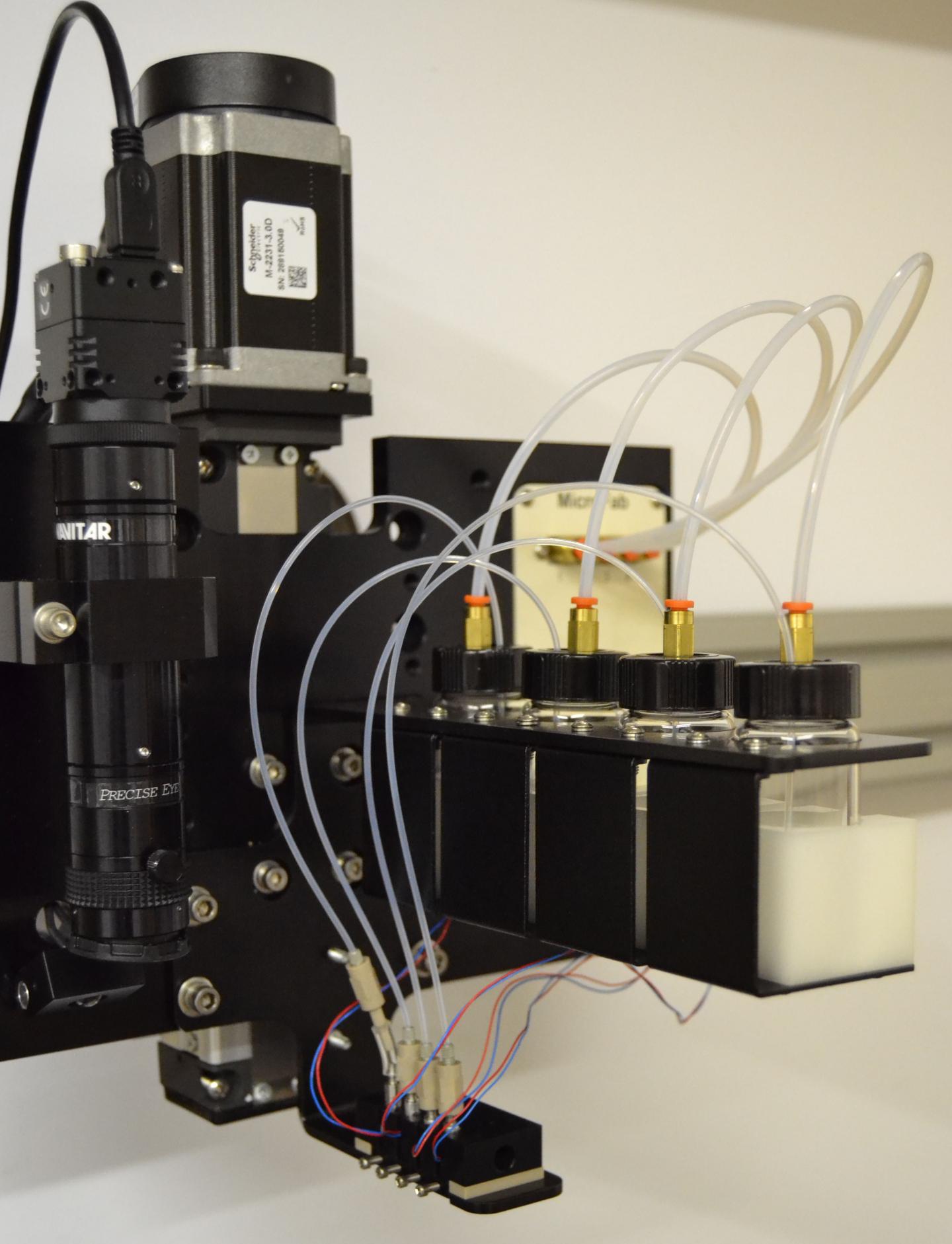

4. Multi-Organ Drug Screens

3D bioprinting could also change the way new drugs are tested and evaluated by generating “organoids” made up of multiple cell types, like tumor models with engineered blood vessels. Doing so could make it possible to quickly monitor drug interactions in real time in multiple organs.

“Along with the development of novel advanced bioprinting techniques, fabrication of physiologically relevant tissue models will become a vital tool in pharmaceutical development in the next decade,” write Ibrahim Ozbolat and Weijie Peng of Pennsylvania State University and Derya Unutmaz of The Jackson Laboratory of Genomics Medicine. “Integrating with other 3D biofabrication and supporting techniques, bioprinted organ/human-on-a-chip models and microarrays will significantly decrease the attrition rate of new therapeutics in preclinical trials and significantly shorten the drug development process.”

5. Plug-in Blood Vessels

Another way to employ 3D bioprinting, which is currently in the works, is the creation of 3D blood vessel networks within bioengineered tissues. These would be necessary to ensure tissue survival after implantation and an accurate replication of human anatomy.

Currently, researchers are working on stacking 2D layers of cells or bioprinting 3D networks, but still need to figure out how to create tissues with blood vessel networks that could directly connect to a patient’s arteries or veins.

“Vascularization is currently regarded as one of the main hurdles that need to be taken to translate tissue engineering to clinical applications at a large scale,” write Jeroen Rouwkema and Ali Khademhosseini, both bionegineers of MIT and Harvard. “It is clear that approaches that focus on the active patterning of vascular cells within engineered tissues provide the highest level of control over the initial organization of vascular structures.”

The research will be published n a Trends in Biotechnology special issue on biofabrication this month.

Story via Eurekalert.

Comments are closed, but trackbacks and pingbacks are open.