Engineers 3D print with reactive materials, manipulate energy released

A team of engineers from Lawrence Livermore National Laboratory and Harvard University have been working with reactive materials and have just figured out a way to 3D print with them.

While reactive materials are found in so many places, like airbags or fireworks, researchers find that a major challenge in working with them is that their reactions can be unpredictable.

Research has shown that one way to manipulate reactive materials’ performance is to either change the formulation, or to change parameters, like particle size, within a formulation. However, these engineers have discovered that 3D printing can play a role in exerting more control over the energy release rate of reactive composites.

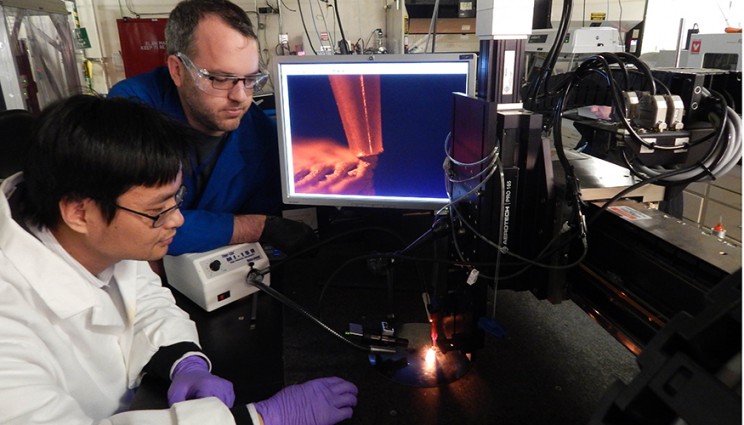

“3D printing has allowed us to make high-quality parts with the feature sizes commensurate with the length scales of dynamic phenomena,” said Kyle Sullivan, a staff scientist and the paper’s lead author. “It’s allowed us to make precision geometries, with careful control over several length scales. With this spatial control, we wanted to examine how, and to what extent, this translates into controlling dynamic behavior.”

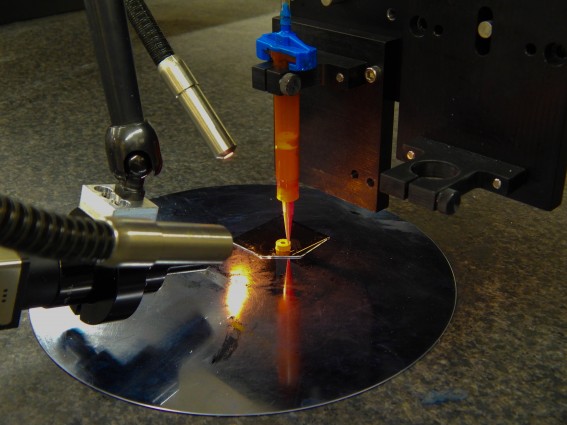

The team used a 3D printing process called direct ink writing to construct 3D conductive electrodes and then used a process called electrophoretic deposition (EPD) to coat the surface of the conductive micro-architectures with a composite film of thermite nanoparticles. In doing this, the team found that it could direct and manipulate the energy released by the material.

“The big message here is we’re showing 3D printing can be used to change the dynamic behavior of materials,” Sullivan said. “It’s very promising moving forward.”

3D printing has allowed the engineers to be more precise with their measurements.

“Traditional thermites are random mixtures of materials,” said Eric Duoss, Lab engineer. “EPD gives you a tool to fix the mixing scale at the nanoscale. The film thickness, micro- and macroscale geometry can then be examined to elucidate the role of architecture on reactivity.

The new technique could lead to new structural energetics, the discovery of previously unknown functions for reactive materials, and even improve the safety and reliability of air bags, ejector seats or other items requiring a quick burst of energy.

Comments are closed, but trackbacks and pingbacks are open.