Engineers use laser beams to write with bubbles

Engineers from The University of Texas at Austin have been doing some writing — not with a ball point pen — with a bubble pen that uses lasers to help it focus. Their new technique may help researchers easily create tiny machines, biomedical sensors, optical computers, and solar panels.

The newly developed device and technique, called bubble-pen lithography, can efficiently and gently handle nanoparticles — the tiny pieces of gold, silicon and other materials used in nanomanufacturing, by relying on microbubbles to write nanoparticles onto a surface.

There’s been a recent interest in nanoparticles, which are between 1 and 100 nanometers in size, due to their versatility and strength. Some nanoparticles have optical properties that are useful for electronics, while others have the ability to absorb solar energy. In biomedical applications, nanoparticles can even act as drug carriers or imaging agents.

Although they are an asset to many applications, the challenge for researchers has been keeping their properties and functions intact. Unfortunately, existing lithography methods, used to etch materials on a substrate, are not capable of fixing nanoparticles to a specific location with precise and arbitrary control.

To solve the problem at hand, the UT engineers developed a method for handling the small particles without causing damage.

How they did it

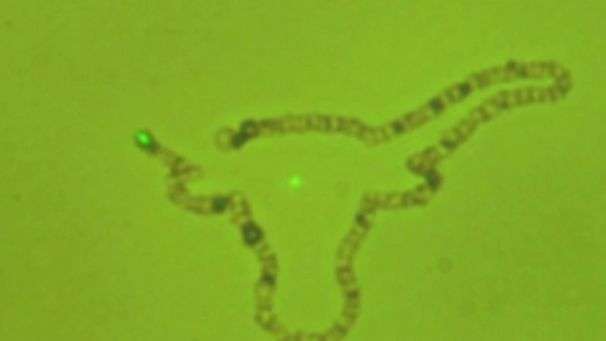

The engineers used microbubbles to gently transport the particles. With the bubble-pen device, they were able to focus a laser underneath a sheet of gold nanoscale islands to generate a hot-spot that created a microbubble out of vaporized water. The bubble attracted and captured a nanoparticle through a combination of gas pressure, thermal and surface tension, surface adhesion and convection. They then used the microbubble to move the nanoparticle on a site on the surface. When the laser was turned off, the microbubble disappeared and the particle remaine on the surface. If they needed to, the researchers could expand or reduce the size of the microbubble by increasing or decreasing the laser beam’s power. The technique allowed them to quickly arrange particles in various shapes, sizes, compositions and distances between nanostructures.

“The ability to control a single nanoparticle and fix it to a substrate without damaging it could open up great opportunities for the creation of new materials and devices,” said Yuebing Zheng, Assistant Professor who led the Texas Engineering team. “The capability of arranging the particles will help to advance a class of new materials, known as metamaterials, with properties and functions that do not exist in current natural materials.”

The technique could play a major role in science and medical applications because researchers would be able to precisely control cells, biological material, bacteria or viruses for study and testing, according to the team.

What’s next?

The new technique can be used to test prototypes and ideas for devices and materials at a faster rate and has the potential for large-scale, low-cost manufacturing of nanomaterials and devices.

Zheng hopes to advance bubble-pen lithography by developing a multiple-beam processing technique for industrial-level production of nanomaterials and nanodevices and is planning on a mobile version of the new technology for future mobile electronics.

Story via University of Texas Austin.

Comments are closed, but trackbacks and pingbacks are open.