The Aircraft Of The Future In The Making

A supercomputer tool that can optimize airplane wing design offers improved detail due to a team of researchers from the Technical University of Denmark who applied a new engineering technique to design the interior of an airplane wing. The design is 2-5% lighter than normal designs.

In their paper published in the journal Nature, the team describes creating a tool to bring the number-crunching power of a supercomputer to a common engineering problem, and what the results suggest about future engineering endeavors.

Matthijs Langelaar with Delft University offers a News & Views perspective piece on the work done by the team in the same journal issue.

Over time, mathematicians, engineers, computer scientists and researchers in other fields have contributed to optimization methods for the design of new objects, machines and related parts.

One such technique is known as morphogenesis, in which a general design is produced and then successful improvements are made over time. Improvements are often made while balancing multiple factors such as performance, cost or weight.

Langelaar noted that the technique is, in essence, a process of rearranging material in a given component. Morphogenesis computer programs have been created to speed the process along, but require so much computing power that they are mostly only useful for the design of simple component parts.

In this new effort, the researchers have created a tool that can be used on a supercomputer, making it possible to offer much more detail.

Voxels are used when representing three-dimensional objects in a computer, rather than the two-dimensional pixel. As a higher number of smaller pixels offers better screen resolution, a higher number of smaller voxels offers better resolution and detail for three-dimensional objects.

Current computers generally have a resolution of five million voxels. The new tool developed by the team in Denmark operates with a resolution of more than a billion voxels.

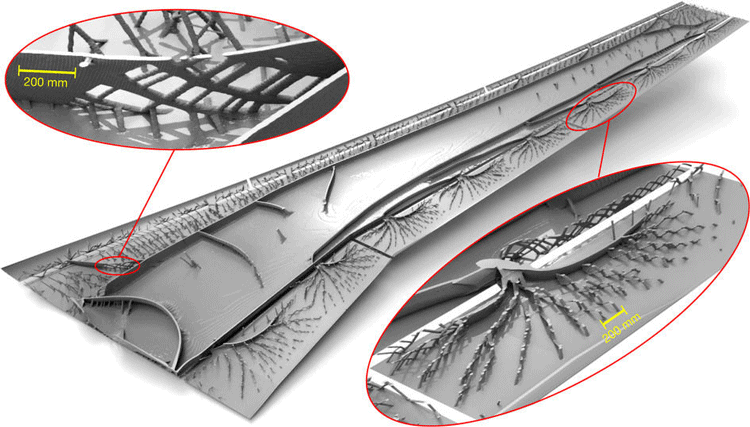

To demonstrate the effectiveness of their new tool, the researchers applied it to the interior design of an airplane wing. Using 8,000 processors running over the course of several days, the computer developed a model that the researchers claim is 2-5% lighter than current designs.

Translated to the real world, they calculate that such a savings in weight would result in a Boeing 777 airplane having wings 200 to 500kg lighter than those in use today which they further calculated would result in a savings of 40 to 200 tons of fuel per year.

Unfortunately, actually building the wing developed using the new tool is not technologically feasible at this time, but the results, the researchers suggest, show what is possible for other components.

Comments are closed, but trackbacks and pingbacks are open.