With a collaborative robot Semcon will automate analysis of samples for an international laboratory company. The objective is to create a faster, safer process and free up time for laboratory personnel so that they can focus on more advanced tasks.

Laboratory work often involves a number of monotonous and repetitive elements that can be streamlined by means of automation. At the same time, this work requires a high level of precision so that no samples are contaminated.

“These new collaborative robot types are safer, quieter and more efficient, because they have been designed to work alongside people. This means that the robot can stand freely in the laboratory and not be surrounded by protective equipment, while well-trained laboratory personnel can focus on more advanced tasks,” said Thomas Lydhig, technical project manager at Semcon.

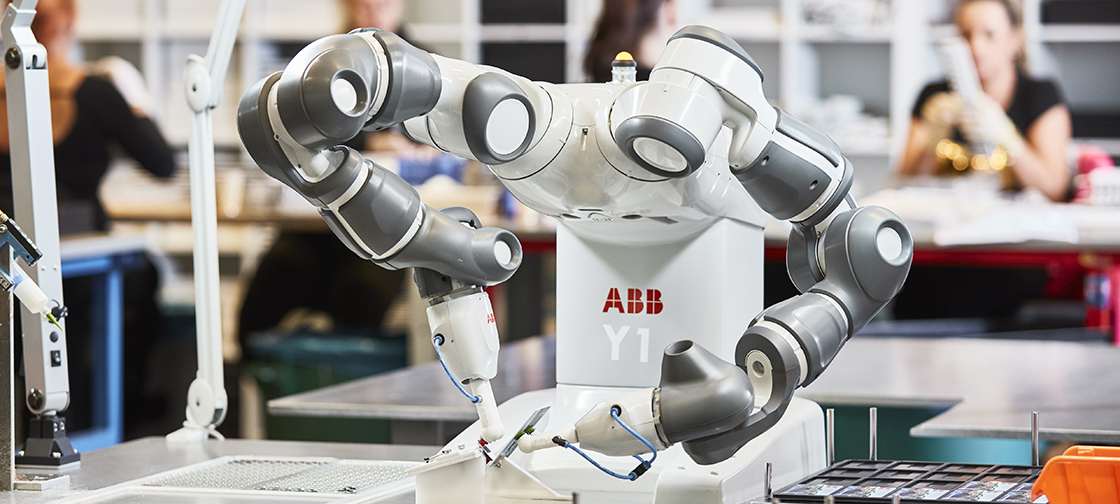

Semcon has overall responsibility for the project, from planning and design to programming and installation. The YuMi collaborative robot is being provided by Semcon’s partner ABB. The robot will be able to handle 50 samples an hour, so work will be completed twice as quickly.

“The collaborative robot is about the same size as a human torso and has two arms that work simultaneously. The robot also has cameras in both hands so that it can read labels and see the positions of test tubes, for instance. It is also possible to connect the robot’s cameras so that humans can see what the robot is seeing,” added Lydhig.