For decades, making electronic circuits has been a story of heat. Whether it’s firing up silicon wafers in furnaces, baking on conductive films, or sputtering metals under vacuum, the process has always relied on high temperatures and complex machinery. That reliance has shaped how and where electronics are made—and it has also limited how far flexible, transparent, or truly unconventional devices could go.

But a team of researchers recently decided to rewrite that story. Instead of starting with fire, they turned to something as simple as a droplet of liquid metal. What they discovered is a printing technique that lets you draw ultrathin oxide circuits at room temperature, no heat required, using nothing more exotic than the natural oxidation that happens when liquid metal meets air.

The results, published in Science and highlighted by Semiconductor Digest, sound almost like science fiction: transparent, conductive, flexible films just a few nanometers thick—stable up to hundreds of degrees, strong enough to survive tens of thousands of folds, and versatile enough to be patterned on surfaces ranging from glass to plant leaves. It’s the kind of advance that makes the future of electronics feel a little closer.

A Meniscus With a Mission

The method relies on a meniscus—the curved edge of a liquid drop. The researchers used a small bead of gallium-based liquid metal, the kind that naturally forms a thin oxide skin when exposed to air. By sliding this droplet across a surface, the oxide film at its edge spreads out, coating the substrate as it moves.

It’s a bit like drawing with a metallic ink pen, except the “ink” is the oxide skin constantly regenerating on the moving droplet. Each pass lays down a film as thin as four nanometers, yet continuous and uniform. The trick requires no heat, no vacuum chamber, and no expensive deposition tools. Just ambient conditions, a steady hand—or eventually, a robotic printer head, and some clever physics.

This may sound simple, but the implications are huge. Oxide thin films are a staple in electronics, prized for their semiconducting and transparent properties. Usually, they demand processing at several hundred degrees Celsius. Here, the same kinds of films emerge effortlessly at room temperature.

Conductivity, Transparency, and a Dash of Gold

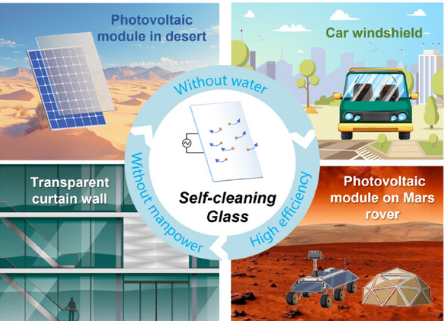

So, what makes these new films different? First, they aren’t just thin, they’re nearly invisible. At a few nanometers, light passes straight through, making them excellent candidates for transparent electronics like displays, smart windows, or wearable sensors.

Second, they conduct. That’s unusual for oxides, which often act as insulators. But the films produced by this droplet-printing method show metallic conductivity, enough to carry current reliably in circuits. The researchers took it further by adding a thin topping of gold. Normally, gold and oxides don’t play nicely, but here the combination proved synergistic: the gold helped lock in conductivity, stabilize the surface, and block oxygen diffusion that could degrade performance over time.

It’s a tiny gilded touch that makes the films not only functional, but durable.

Built to Bend, Made to Withstand Heat

Flexible electronics are nothing new in concept, but in practice, most materials crack, peel, or lose conductivity when bent repeatedly. These printed oxide films are different. Tests showed they held up after more than 40,000 folding cycles—the kind of punishment that would destroy many conventional conductors.

On the opposite end of the spectrum, the films also shrugged off high heat. Thin versions (about 4 nm) stayed conductive up to 600 °C. Thicker ones (around 12 nm) endured 800 °C without losing their properties. That’s an impressive thermal stability for a material laid down at room temperature, and it points to applications in both rugged industrial environments and delicate wearable devices.

The combination of bendability and heat resistance is rare, and it’s what makes this work stand out. Electronics that can survive both extremes—being folded like paper or blasted like metal—open doors to design possibilities not easily imagined before.

Circuits on Leaves and Other Unlikely Surfaces

One of the more charming demonstrations of the technique involved printing circuits on a leaf. The oxide films adhered seamlessly, forming conductive traces on the natural, irregular surface. While this isn’t exactly how we’ll be powering forests in the future, it highlights how adaptable the method could be.

Imagine sensors printed directly onto biodegradable materials, or transparent circuits integrated into packaging, textiles, or even living plants. The room-temperature nature of the process means delicate substrates won’t be scorched or damaged during fabrication.

Why It Matters

It’s easy to dismiss incremental advances in thin films as lab curiosities. But the appeal here lies in scalability and simplicity. Instead of high-temperature furnaces or vacuum chambers, this technique suggests a world where electronics could be printed like newspaper ink. That lowers costs, expands accessibility, and enables designs impossible with rigid silicon-based methods.

For engineers, the promise is practical: transparent conductors for displays, flexible circuits for wearables, rugged sensors for harsh environments—all fabricated under conditions gentle enough to be almost DIY. For the industry, it’s a potential paradigm shift in how we think about making electronics at scale.

The Story Ahead

Of course, like all new techniques, questions remain. How well can this printing process be automated? What’s the resolution limit for complex circuit patterns? And how do these films behave over months or years of operation? Those answers will determine whether the work stays in the realm of research or migrates into commercial products.

But the foundation is strong: a room-temperature, low-cost, versatile way to print oxide circuits that are thin, transparent, conductive, heat-resistant, and flexible. It’s a rare blend of traits, and it may prove to be the key that unlocks the next generation of electronics.

In the meantime, it’s worth appreciating the elegance of the discovery itself. Sometimes innovation isn’t about building a bigger furnace or a faster etcher—it’s about noticing that a droplet of liquid metal, left to do what it naturally does, can become a pen for the future.