A research team at the University of Arkansas’ UA Power Group has successfully demonstrated a more compact, efficient electric motor drive system tailored for aviation. They conducted a test flight using a hybrid aircraft (a modified Cessna 337) equipped with a new silicon-carbide (SiC) motor inverter designed in-house.

Why This Matters

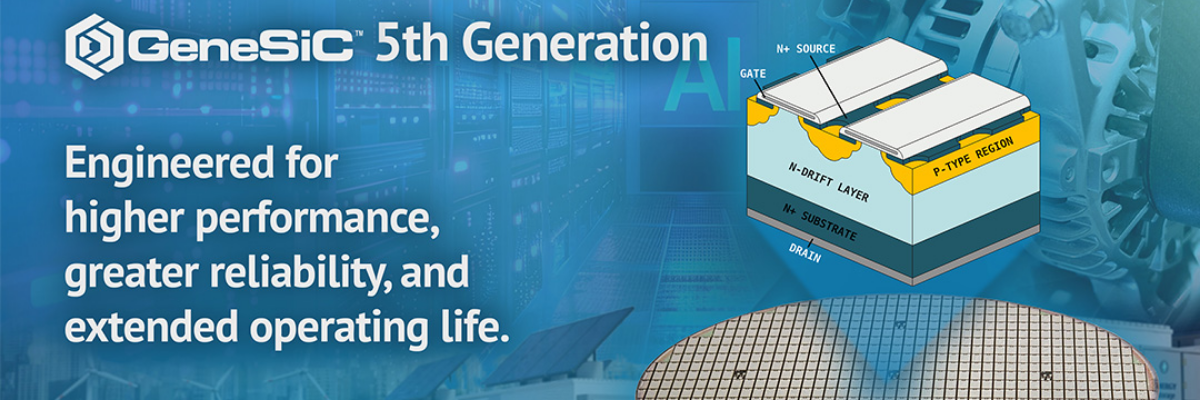

In aviation, size and weight directly impact performance and efficiency. Traditional silicon-based inverters and motor drives carry significant mass and require bulky supporting components. By switching to silicon-carbide transistors, which switch much faster than silicon, the UA team reduced the size and weight of the supporting circuitry dramatically. Faster switch speeds allow inductors, transformers and capacitors to shrink, which ultimately cuts system size and weight.

The Technical Approach

The UA Power Group built an SiC-based inverter for the hybrid aircraft. While silicon transistors manage switching with some delay and energy loss during state transitions, the SiC devices switch roughly 1,000 times faster. That efficiency gain translates into smaller passive components and reduced thermal burden, which are critical for aircraft applications.

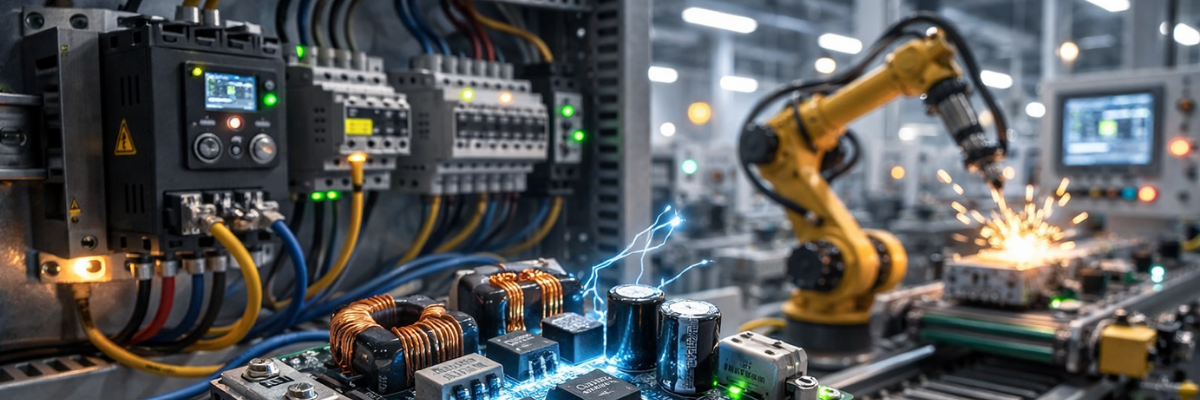

During a demonstration flight with the hybrid Cessna, the new system handled the drive demands of the electric motor in real-world conditions, showing the practical viability of the approach beyond lab prototypes.

Engineering Implications

-

Weight and space savings: A lighter drive system reduces takeoff weight and improves cruise efficiency.

-

Component scaling: With faster switching, the passive components required can be smaller, simplifying system design.

-

Reliability in flight conditions: Aircraft electrical systems must handle vibration, shock and partial-discharge conditions at altitude. The SiC-based system met those real-world demands.

-

Path to broader adoption: As SiC manufacturing costs fall and system design adapts, this architecture may enter more aircraft, whether hybrid or fully electric.

What’s Next

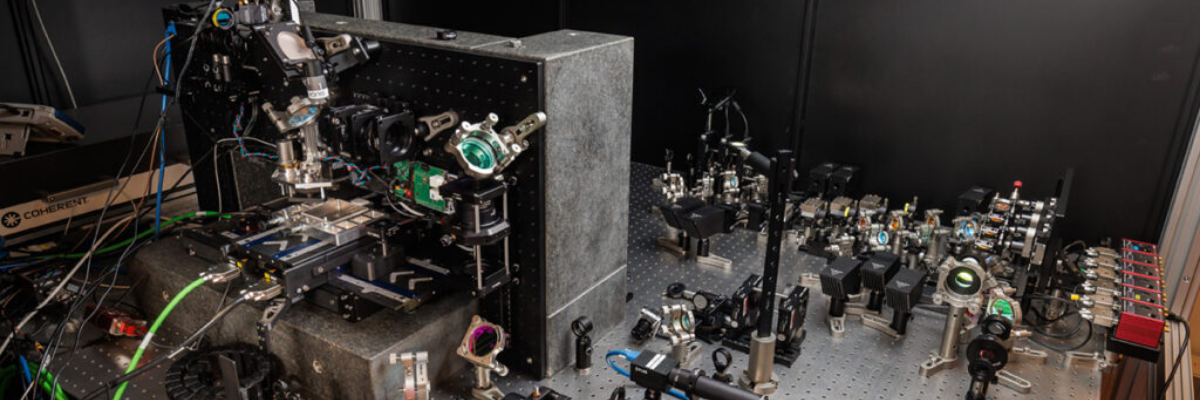

While the test is a milestone, broader implementation still requires work. Scaling the system for production aircraft, optimizing cost, and addressing long-term performance under aviation stress remain key challenges. The UA team is advance planning to support SiC fabrication research through a new multi-user facility linked to their lab, signaling their intent to push the architecture toward commercial viability.

For engineers working on electric aviation, this development offers a meaningful shift in inverter and motor-drive design options — one that couples high-performance semiconductor devices with system-level weight and efficiency benefits.