The term ‘CO2 emissions’ usually brings to mind predominately negative things: greenhouse gas, pollutant, climate change, political discord, economic burden. But a team of researchers led by Stuart Licht, a chemistry professor at George Washington University, has a vision for transforming CO2 emissions from a pollutant into a valuable resource—all while making a potentially large net profit.

In a new study published in Materials Today Energy, the researchers have shown that they can use CO2 and solar thermal energy to produce high yields of millimeter-length Carbon Nanotube (CNT) wool at a cost of just $660 per ton. The market value of long CNTs like these—which can be woven into textiles to make metals, cement replacements, and other materials—is currently $100,000-$400,000 per ton.

“We have introduced a new class of materials called ‘Carbon Nanotube Wool,’ which are the first CNTs that can be directly woven into a cloth, as they are of macroscopic length and are cheap to produce,” Licht told Phys.org. “The sole reactant to produce the CNT wools is the greenhouse gas carbon dioxide.”

The researchers hope that the new technology, called C2CNT (CO2 to CNTs), will offer an indisputable economic incentive to remove excess CO2 from the atmosphere.

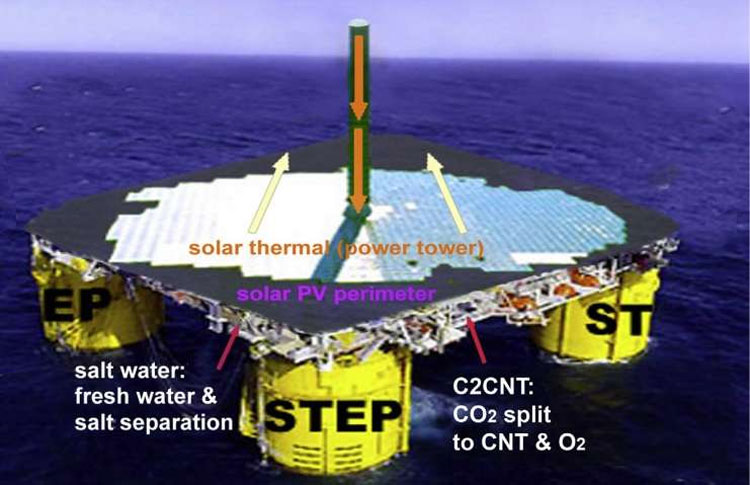

They calculate that, if they were to set up solar thermal stations over an area equal to 4% of the Sahara Desert, they could reduce the CO2 concentration of the atmosphere back to pre-industrial levels in 10 years. They note that a more realistic implementation would be to set up stations on the oceans, where there is more available surface area.

The new study builds on the scientists’ previous research going back to 2010, when they first proposed the idea of a solar thermal electrochemical process (STEP), in which solar energy is used to power an electrolytic cell. This cell captures and breaks down, or electrolyzes, atmospheric CO2 into carbon or carbon monoxide and oxygen. The carbon byproducts can then be used to synthesize various products, such as methane, syngas, and ammonia. Although useful, these products are valued at around $100 per ton, and so are not nearly as valuable as CNTs.

Synthesizing CNTs from CO2 emissions has proved to be more challenging, with some earlier research suggesting that it may be impossible to produce CNTs by electrolysis using molten lithium carbonate, which is the compound used in the STEP process to nucleate the growth of the carbon products. However, in 2015, Licht and his team demonstrated for the first time the feasibility of high-yield, low-energy electrolytic splitting of CO2 into CNTs, which uses an alternative growth mechanism with molten lithium carbonate.

One drawback of that process, however, is that the CNTs it produces are nanometer-sized (less than 100μm long), which is too short to be woven into textiles.

The main result of the new study is that the CNTs are 100 times longer, which is achieved by replacing the copper or steel cathodes on the electrolytic cell with Monel, a type of nickel-copper alloy.

By making this change and carefully tuning other parameters, the researchers produced CNTs with diameters of more than 1μm and lengths of more than 1mm—which, they point out, raises the question of whether the CNTs should actually be classified as ‘nanomaterials’. In any case, the wool-like CNTs are long enough to be woven into textiles for various applications.

“Inexpensive, weavable CNT wools are preferred replacements for conventional steel and aluminum applications, due to the CNT wool’s lightweight, strength-to-mass advantage,” Licht said. “In addition to textiles, CNT wools serve as preferred additives to formulate blast- and fracture-resistant cement and ceramics. Other applications of stronger-than-steel, highly conductive CNT cloth are bullet-proof CNT suits and taser-proof suits.”

Comments are closed, but trackbacks and pingbacks are open.