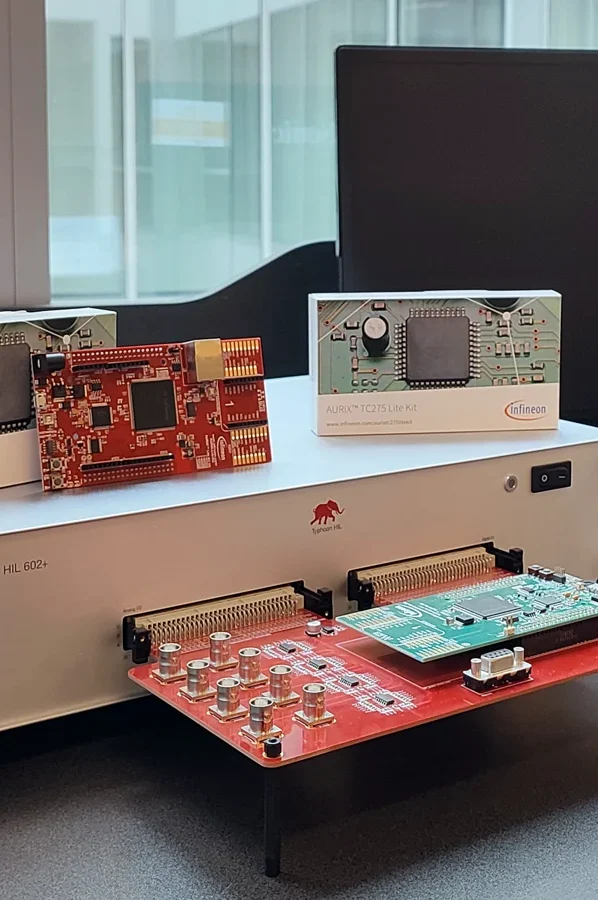

In a bid to fast-track the design and validation of electric vehicle (xEV) systems, Infineon Technologies AG has teamed up with Typhoon HIL to integrate a real‑time hardware‑in‑the‑loop (HIL) testing platform into its workflow. This strategic collaboration aims to streamline development cycles, cut costs and reduce complexity for engineers working on power electronics solutions—critical components in modern EVs.

Tackling Validation Bottlenecks

The core of this partnership is the deployment of Typhoon’s robust HIL simulation environment. Infineon will leverage this platform to emulate xEV powertrain components and their interactions in real time. By simulating converters, inverters and other key hardware with high precision, developers can test and refine systems before hardware prototypes even exist. Infineon expects this capability to substantially speed up validation phases and improve design accuracy.

Why It Matters for xEV Innovation

As electric vehicles become more sophisticated, constraints like efficiency, reliability and thermal management are becoming increasingly complex to model. Hardware‑in‑the‑loop platforms offer a crucial advantage by replicating real‑world electrical, thermal and dynamic behavior in the laboratory. Infineon believes this will tighten integration between software and hardware teams, uncover integration issues early, and ultimately reduce engineering costs.

A Win for Developers and End‑Customers

EV system developers stand to benefit from faster iteration loops and more agile troubleshooting. Infineon’s customers can expect faster time‑to‑market, fewer integration hurdles, and more power‑optimized systems. In turn, EV manufacturers may see improved performance, quicker rollouts, and enhanced system dependability.

How the Collaboration Fits

Infineon, a global leader in power semiconductors, has made significant strides in automotive electrification over the last years. This strategic move builds on their existing momentum in providing semiconductor components for OEMs and Tier‑1 suppliers. Partnering with Typhoon HIL reflects Infineon’s holistic approach—linking Silicon‑level design with system‑level simulation and validation.

On Typhoon HIL’s side, this deal highlights growing recognition of its simulation solutions among premier semiconductor players. As Infineon’s xEV customers adopt these HIL workflows, Typhoon’s tools will be rigorously tested in real‑world batch environments—likely fueling further product enhancements.

Looking Ahead

Infineon and Typhoon HIL haven’t publicly shared the timeline for broader rollout, but both companies indicate the collaboration is already underway. Over the coming months, system developers may expect to hear about pilot projects showcasing more efficient converter designs, smoother integration, faster validation, and cost-optimized production cycles.

This collaboration sets a new benchmark in electrification tools, spanning silicon innovation to full system testing—all aimed at better, faster, and more reliable power electronics for the next generation of electric vehicles.

Learn More: Typhoon HIL – Infineon Technologies