Designing power systems for space or radiation-exposed environments is rarely straightforward. Engineers have long relied on complex arrangements of discrete components to make converters reliable enough to survive the harshest conditions.

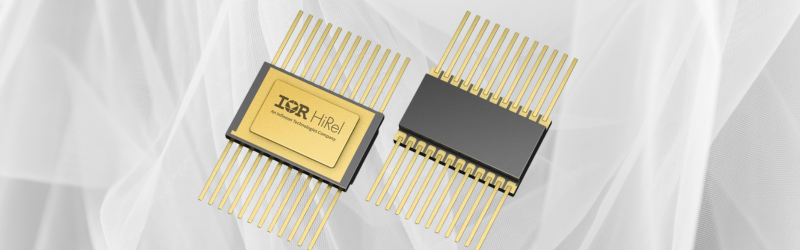

Infineon has unveiled a radiation-hardened buck controller with an integrated gate driver, the first of its kind, simplifying power stage design for applications where reliability isn’t optional.

Why It’s a Big Deal

Buck converters are the backbone of most electronic power systems, stepping down voltages efficiently for logic and control circuitry. In space, avionics, and other radiation-heavy environments, however, ordinary controllers can’t survive. Engineers typically piece together hardened components from multiple vendors to achieve the required protection — a process that adds complexity, size, and risk.

Infineon’s new device brings the controller and gate drive into one hardened chip, reducing the number of external parts, improving efficiency, and helping designers fit more power into smaller footprints. By combining radiation tolerance with integration, Infineon gives power engineers a cleaner architecture and fewer potential failure points.

Built for Harsh Environments

The new controller is designed to handle both total ionizing dose (TID) and single-event effects (SEE) — the two primary radiation hazards that cause long-term degradation or sudden malfunction in electronic systems.

That means it can run reliably in environments where standard parts would fail, including satellites, launch vehicles, and high-altitude avionics. With the gate driver built in, engineers can focus on optimizing the external MOSFETs, passive components, and board layout instead of managing separate driver circuits.

Engineering Benefits

-

Simplified layout: Integration reduces board space and minimizes interconnect parasitics.

-

Higher reliability: Fewer components mean fewer solder joints and fewer single-event failure paths.

-

Design consistency: Radiation-qualified parts improve confidence in long-duration missions where repairs aren’t possible.

-

System-level efficiency: With gate-drive timing and controller logic co-optimized, switching losses and noise can be better managed.

Raising the Bar for Space-Grade Power Design

Radiation-hardened components are never about cost; they’re about mission success. By merging functionality that once required multiple chips, Infineon is helping design teams streamline development, simplify qualification, and move toward more compact, efficient, and reliable power architectures.

For engineers pushing electronics beyond Earth’s atmosphere — or anywhere reliability is non-negotiable — this new controller offers a cleaner way to get there.

Learn More: Infineon launches industry’s first radiation hardened b | Infineon Technologies