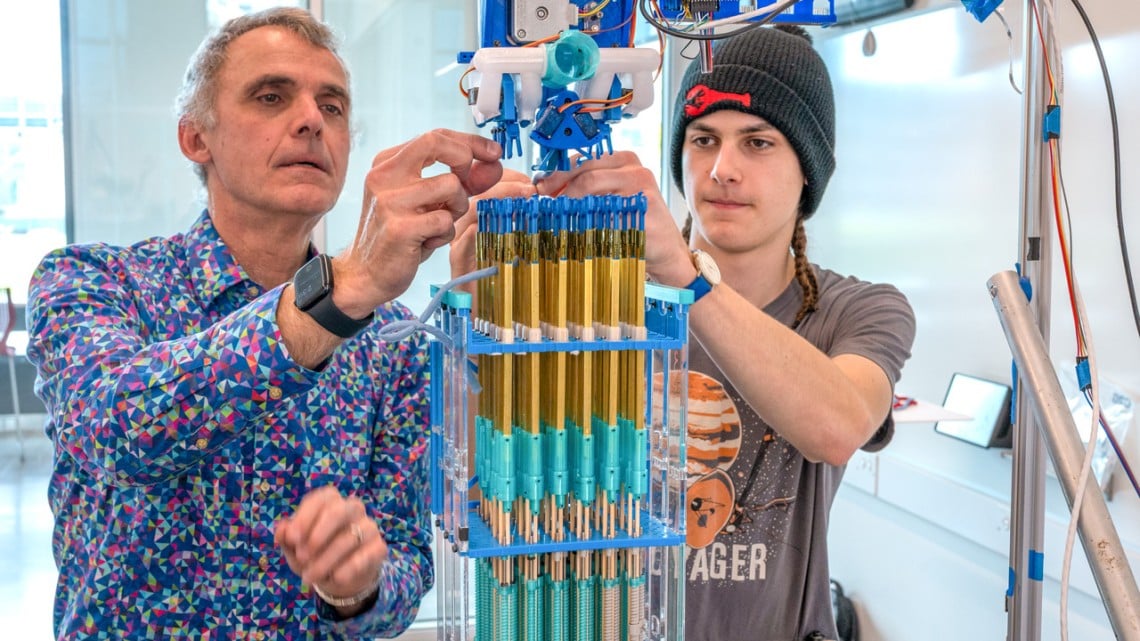

A research team from Cornell University and Carnegie Mellon University has developed a new kind of knitting machine capable of building solid three-dimensional objects from yarn. Unlike traditional knitting machines that produce flat sheets, this prototype forms volumetric structures by stacking layers of stitches, pushing textile manufacturing closer to additive manufacturing.

Moving Beyond Flat Fabric

Conventional machines lay out stitches in a plane. This system works more like a 3D printer: it can knit forward, backward, diagonally, and across multiple layers to form real volume. By precisely controlling how each loop is created, the machine can fine-tune stiffness, thickness, and other mechanical properties throughout an object.

How the Machine Works

-

A 6×6 bed of needles uses a custom double-hook mechanism that can independently form knit and purl stitches.

-

A mobile knitting head carries the yarn and can travel freely over the needle array, enabling complex shapes and overhangs.

-

Custom software translates 3D geometries into stitch-level instructions, allowing designers to specify how the internal structure should vary within the finished object.

Early Demonstrations

The machine has already produced simple volumetric shapes like a “C” and a pyramid. These early builds show promise, though the team notes that the prototype is slow, occasionally drops loops, and can snag yarn—normal growing pains for a first-generation system. Improvements in robustness, speed, and needle-bed size are already planned.

Why This Matters for Design Engineers

This approach opens a new frontier where textiles intersect with additive manufacturing. By controlling stitch direction, density, and layering in three-dimensional space, engineers can create structures with:

-

Tunable stiffness or thickness

-

Internal gradients or patterned mechanical responses

-

Low-cost, flexible, or biocompatible materials

-

Complex geometries without assembly steps

Potential applications range from soft robotics to wearables and biomedical scaffolds that mimic natural structures such as ligaments or veins.

What Comes Next

Key questions moving forward include:

-

Can the system scale to larger parts and finer resolution?

-

Will functional yarns—conductive, composite, or high-strength—expand its use in electronics or sensing?

-

How will these knitted 3D structures integrate into larger engineered systems?

-

What design tools will emerge to let engineers fully exploit stitch-level control in 3D space?

Original Story: Knitting machine makes solid 3D objects | Cornell Chronicle