Electric vehicle engineers are constantly wrestling with the same challenge: how to deliver more power in less space while keeping efficiency high. Inverters sit at the heart of this puzzle. They are responsible for taking battery power and turning it into the rapid pulses that keep electric motors spinning. Push the limits too far, and systems run hot, bulky, or unreliable. Hold back, and the vehicle loses the performance and charging speeds that drivers expect.

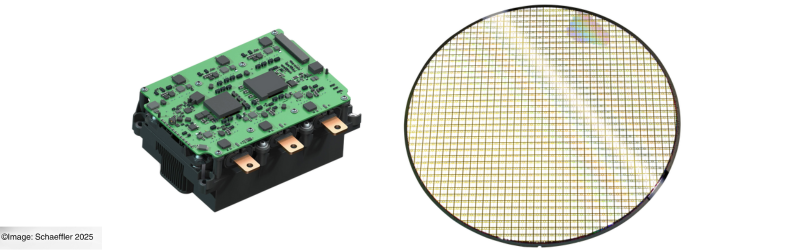

That gap between what is needed and what has been possible is where a new development from Schaeffler and ROHM fits in. Schaeffler has begun mass production of a compact inverter brick that integrates ROHM’s fourth-generation silicon carbide (SiC) MOSFET chips. Built as a modular building block, this subassembly is already moving into production vehicles for a major Chinese automaker.

Building Blocks for High Voltage Drives

The inverter brick provides the essential stage that shapes current for the motor. By using SiC technology, Schaeffler has been able to raise the maximum battery voltage well beyond the typical 800 volt level while handling root mean square (RMS) currents up to 650 amps. That combination delivers a high-power output in a package small enough to fit into scalable inverter designs.

For engineers working on multi-in-one e-axle platforms, the new brick simplifies integration. It arrives as a ready-to-use submodule that can slot directly into broader inverter systems without major redesign.

Inside the Subassembly

The design includes the core power module for pulse width modulation of current pulses, a DC link capacitor, the DC link itself, and liquid cooling. One of its most notable features is an integrated DC boost function. With this circuit, vehicles designed for 800 volt operation can still charge at 400 volt stations without slowing down, a useful bridge for today’s uneven charging infrastructure.

Why SiC Matters Here

Silicon carbide devices bring lower switching losses and higher thermal conductivity than traditional silicon IGBTs. For this inverter brick, that means more current handling in a smaller footprint, along with improved efficiency at high switching frequencies. The result is not just higher peak power, but also less wasted energy across real driving conditions.

A Partnership with Momentum

Schaeffler and ROHM have been working together on e-mobility platforms since 2020. In 2023, the companies signed a long-term supply agreement to secure SiC capacity and align roadmaps. The new inverter brick marks one of the first mass production results of that collaboration and sets a template for future modular power electronics.

For engineers, the takeaway is clear: the combination of modular inverter design and advanced SiC devices is beginning to solve long-standing bottlenecks in EV powertrains. Higher voltage operation, faster charging compatibility, and compact integration are no longer research goals. They are now entering the market in volume.