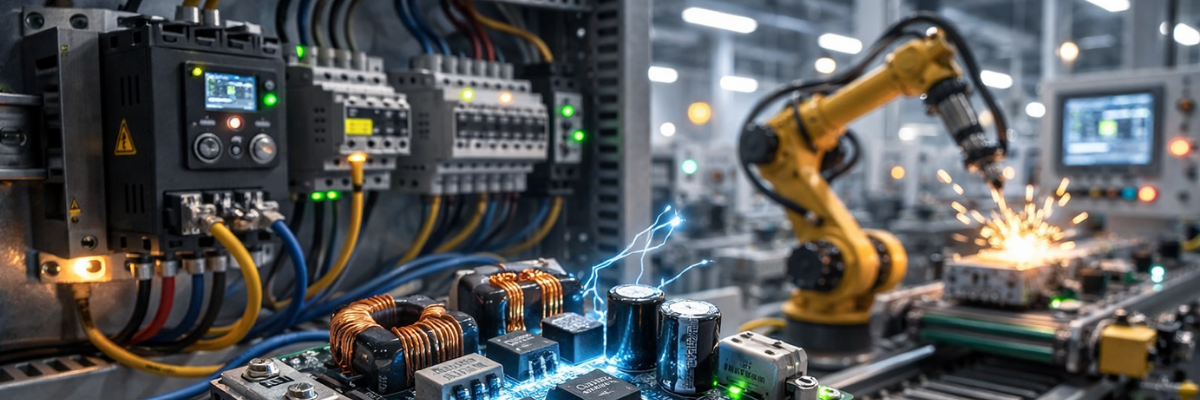

In high-demand industrial environments like plastic recycling and extrusion, system efficiency, thermal management, and drive reliability are critical to operational success. FAE SRL, specialists in electrical panel design for OEMs in the plastics sector across Italy and Switzerland, needed a drive solution that could meet the rigorous demands of continuous operation, high power density, and seamless integration with modern control architectures.

With a long-standing relationship with Nidec Drives, the company turned to Commander C300 and Unidrive M700 drives to power its latest generation of extrusion systems.

For more than 40 years, FAE has been a globally active Italian company that designs and delivers custom automated systems for industrial clients. A trusted provider of automation engineering services; FAE aids factories and production lines to run more efficiently, safely, with less intervention, and following internationally recognized quality management practices. Responding to global competition and market demands FAE adopted Lean Management and Lean Production, thus entailing their operations are streamlined to reduce waste, improve efficiency and manufacturing processes are optimized for better quality and faster delivery.

For their latest project, FAE once again turned to Nidec Drives building on decades of trust, product reliability, and exceptional technical support that have defined their long-standing partnership.

What is a plastic material regeneration system?

Also known as plastic granulation or extrusion recycling, this process converts landfill-sourced or post-consumer plastic waste into reusable plastic granules. These granules support a circular economy by serving as raw materials for new plastic products.

To do this, plastic waste is collected and organized by type such as, Polyethylene Terephthalate, High-Density Polyethylene, Low-Density Polyethylene and Polypropylene. Proper sorting is crucial to ensure quality and avoid contamination. They then go through a thorough wash to remove dirt, labels, and residues, to prepare for processing.

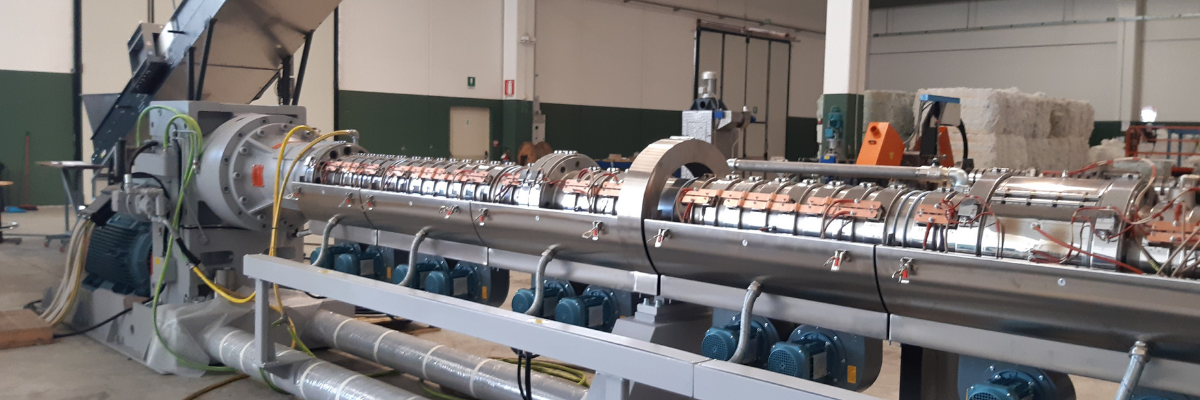

Clean plastic is then shredded into small flakes. If the material is too light, it may be densified, a process that compacts it to improve handling and extrusion. The flakes are fed into a hopper containing a screw mechanism that pushes the material into an extruder. Inside, the plastic is melted and formed into long strands. These strands are then cooled and cut into uniform plastic granules, also known as pellets, which are then ready for reuse in manufacturing.

Why does this matter? This process not only diverts plastic from landfills, reducing environmental pollution and conserving space, but also significantly lowers the demand for new plastic production, which is energy intensive and reliant on fossil fuels. This places the responsibility and opportunity firmly in the hands of manufacturers. By regenerating plastic into reusable granules, OEMs can reduce their carbon footprint and contribute to a more circular economy. Global environmental regulations have tightened, industries are facing increased pressure to adopt sustainable practices, and recycling plastic granules have emerged as a critical resource. Widely used across sectors such as packaging, construction, consumer goods and automotives, they offer a cost-effective and eco-friendly alternative to new plastic materials. Thus, not only does it support sustainability goals, but also enhances supply chain resilience by reducing dependence on raw petrochemical inputs.

Inside the system, FAE’s approach to plastic regeneration

Powered by a carefully engineered combination of mechanical precision and intelligent drive control, this complex system relied on Nidec Drives solutions for their ease of integration, compact design, and communication flexibility. All of which make up key features that align with the demands of their advanced recycling systems.

At the heart of the operation are Commander C300 drives, which control conveyor belts, pumps, and cocles throughout the system, ensuring smooth and efficient material flow. For the high-power demands of the extruders and densifiers, FAE implemented three M700 drives, 500 kW each, a choice driven by their compact footprint, simplified commissioning, and ability to meet power and control requirements without compromising panel space or thermal management.

Commissioning was carried out via Connect software through Profinet, which significantly reduced setup time, compared to other systems that can take up to an hour to program. Nidec Drives intuitive interface allowed FAE to complete the process in just 15 minutes. This ease of programming, combined with competitive pricing and short delivery times, helped FAE stay on schedule and within budget.

The system’s design also accounted for flexibility. While the densifier isn’t continually in use, it plays a crucial part when processing lighter materials, helping to ensure consistent feed into the extruder. Thanks to the adaptability of the drive system, integrating this component posed no operational challenges. Proving FAE’s trust was well placed in a company that shares a commitment to innovation in sustainable manufacturing.

Efficiency in action – real world energy and cost savings

By selecting Nidec Drives products, FAE achieved more than just performance, they unlocked measurable efficiency gains. Compared to alternative solutions, the M700 drives reduced panel power dissipation by up to 2,800 watts, resulting in an estimated 24,528 kWh of energy saved annually. This translates to approximately £3,679 in yearly cost savings, based on average industrial electricity rates. Beyond the direct energy reduction, the lower heat output also decreased the demand on panel cooling systems, contributing to further operational savings and improved system longevity. These benefits, combined with the compact size of the drives, allowed for a more streamlined panel design, maximizing space and minimizing thermal load.

The success of FAE’s plastic regeneration system is a testament to the power of collaboration, innovation, and reliable engineering. FAE was not only able to achieve technical excellence but also benefited from simplified commissioning, reduced energy losses, and a streamlined panel design. Feedback from technicians and operators has been overwhelmingly positive, highlighting the system’s ease of use and minimal technical issues.

FAE summed it up best:

“We are very happy with the collaboration we are having with Control Techniques, and we expect even more partnerships for upcoming projects!”

As the demand for sustainable, high-efficiency systems continues to grow, partnerships like this one demonstrate how smart technology and trusted relationships can drive meaningful progress, both for business and the planet.

About Nidec Drives

We create the world’s motion.

We provide electric drive solutions that add value to our world, from the production of food, movement of materials and people, to keeping us comfortable in any environment.

We are everywhere, we make a difference.

Our precision engineered drives are designed to improve performance, efficiency, and productivity, creating essential motion towards a sustainable future.

For more information, visit www.drivesfromnidec.com