Cooling has always been the Achilles’ heel of modern electronics. As our phones, laptops, and EVs get thinner and more powerful, they also get hotter—and heat is the enemy of performance. Metal helps, but it comes with downsides: weight, rigidity, and the risk of short circuits.

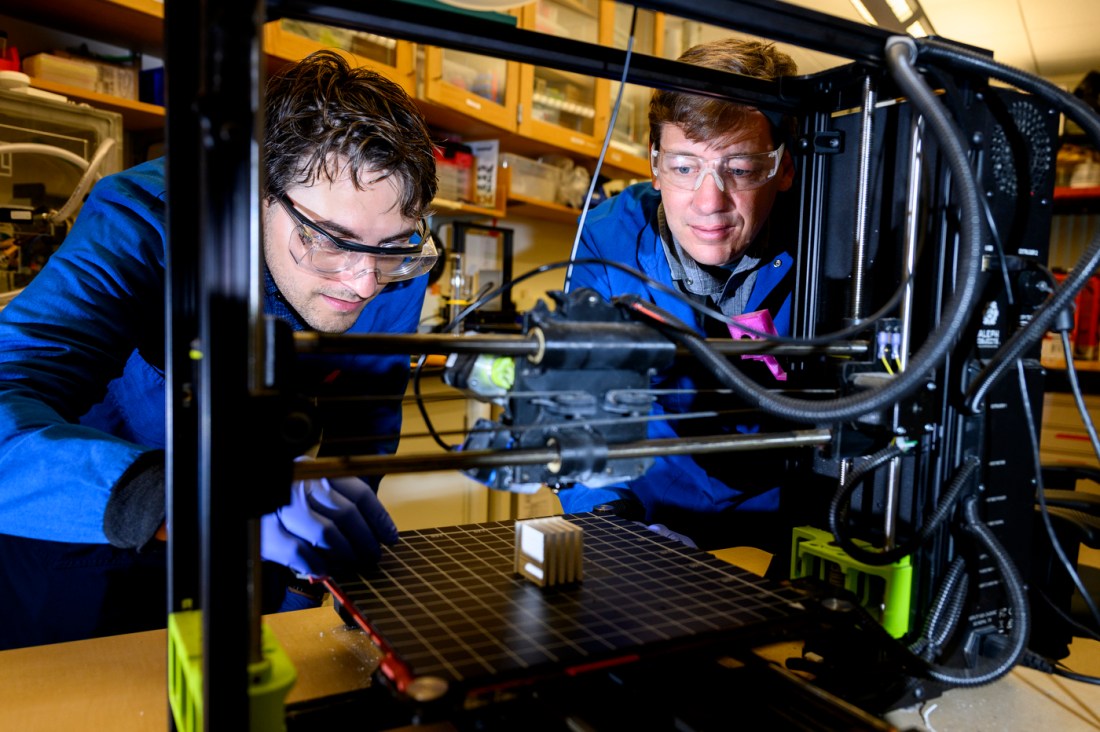

That’s where a team at Northeastern University comes in. Working with the U.S. Army Research Lab, researchers Randall Erb and Daniel Braconnier have developed something that could change the game: a plastic that conducts heat better than stainless steel—but weighs a fraction as much, and won’t interfere with wireless signals or electronics.

Let that sink in. It’s plastic. But it handles heat like metal.

A New Kind of Plastic

Plastics, by nature, are thermal insulators—they trap heat. That’s why your coffee stays warm in a foam cup. But in electronics, trapped heat causes problems: lag, throttling, or total failure. For years, scientists have tried to hack this by mixing plastics with ceramic particles, but the heat flow always hit a wall. The ceramic helped, but the plastic still got in the way.

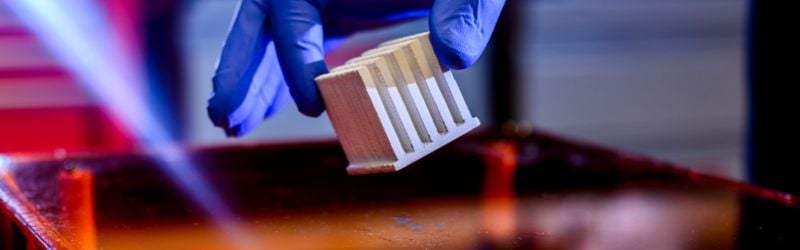

This time, the researchers changed the entire structure—from the molecular level up. Using 3D printing, they precisely arranged ceramic particles into a heat-friendly pattern. Then, they grew tiny crystalline bridges between those particles to create a continuous thermal highway, letting heat move smoothly through the plastic like it would in metal.

The result? A lightweight, printable, and electrically safe material that quietly outperforms stainless steel in thermal conductivity.

Why It Matters

This kind of innovation doesn’t just win awards—it solves real problems. Think about battery packs in electric vehicles or the processors inside data centers. Overheating in these environments can lead to reduced performance or dangerous thermal runaway. Traditional cooling solutions are bulky, heavy, or electrically risky. This new material offers a solution that’s thin, flexible, and safe to use directly next to delicate components.

“It could be wrapped around battery cells to pull heat away,” says Braconnier. “And because it’s an insulator, it doesn’t interfere with the electronics.”

No need for heavy heat sinks or complex designs. Just smarter materials doing the job better.

What’s Next?

The team is now focused on scaling production—making sure this heat-conductive plastic can be manufactured at a level that electronics companies actually need. And with the Army’s backing, they’re not just chasing commercial success—they’re designing for real-world deployment.

Original Story: Scientists Create Heat-Conductive Plastic To Optimize Electronics