Soft robots are making their way into water environments, but fabricating them has always been a fragile process. Most methods start on rigid substrates like glass or silicon. Once the soft films are built, they are peeled away and transferred onto water. That step is where damage usually happens. Films tear, microstructures deform, and performance suffers.

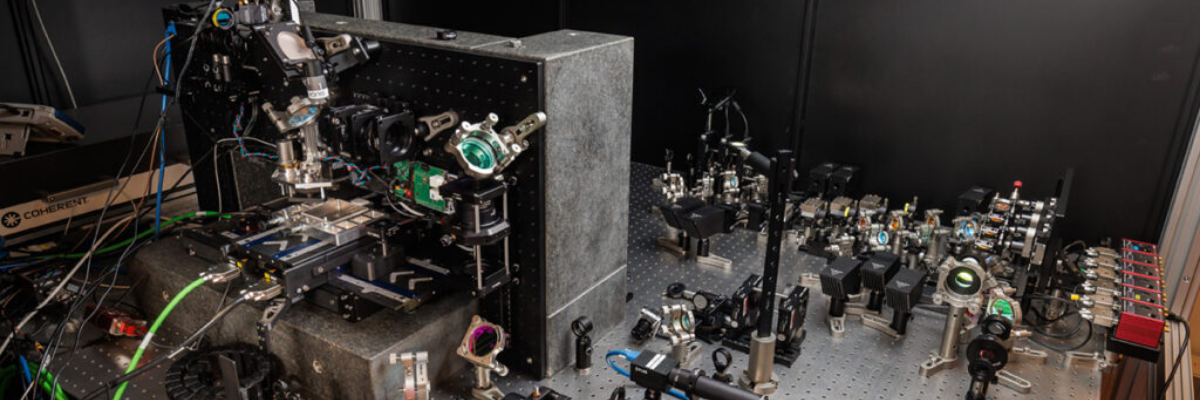

A research team at the University of Virginia led by Baoxing Xu has developed a different approach. Their process, called HydroSpread, builds the robot directly on the surface of water. A liquid polymer is deposited in droplets that spread into an even film. The water acts as the substrate, creating a smooth and supportive base. With the film in place, a laser precisely cuts it into working structures.

Because the device never leaves the liquid during fabrication, the film avoids stresses and cracks. The process integrates formation and patterning in a single step, which makes it more reliable and scalable.

Using HydroSpread, the team created two prototypes. HydroFlexor moves with a finlike paddling motion. HydroBuckler walks by buckling thin strips of the film in a way that resembles the legs of water striders. Both are powered by infrared light. Heating causes the polymer to bend or snap into motion, and by switching the light on and off, the researchers control direction and speed.

The key technical advantage is the ability to define different mechanical responses across the same thin film. The laser can cut shapes that buckle upward in one region and downward in another. That difference in motion produces propulsion without motors or rigid joints.

The applications extend well beyond robotics. A method that reliably produces functional films on liquids could enable new wearable sensors, environmental monitors that operate on rivers or oceans, or soft electronics that survive where silicon cannot.

The prototypes are still at the proof-of-concept stage, moving slowly under controlled lab conditions. But the fabrication technique itself marks a step forward. By eliminating the transfer process, HydroSpread reduces the biggest source of failure in soft robotics built for water environments.