Researchers Master 3D-printing of Wood’s Cellular Architecture

By Ruth Seeley

Just as demand for fake meat has suddenly and dramatically exceeded supply, our need for wood products continues to outpace our ability to grow and harvest the trees we need to make those products.

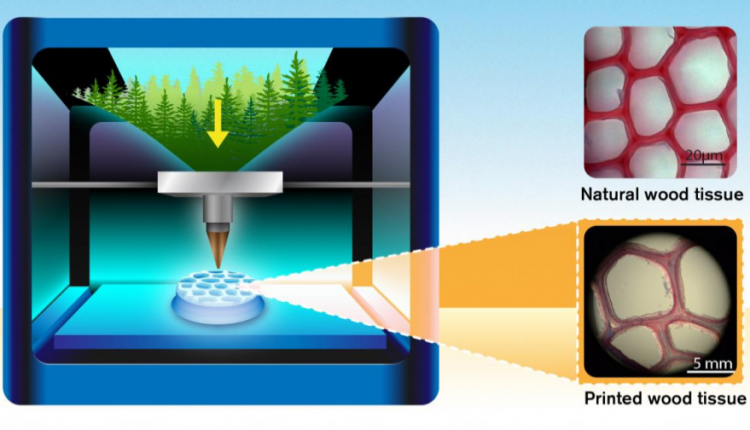

But researchers at Chalmers University of Technology, Sweden, have succeeded in 3D printing tissue with a wood-based ink that mimics wood’s unique ultrastructure, and the research could revolutionize the manufacturing of green products. By emulating the natural cellular architecture of wood, it’s possible to create green products derived from trees, from clothes, packaging, and furniture to healthcare and personal care products.

Wood growth is controlled by its genetic code, which gives it unique properties in terms of porosity, toughness and torsional strength. Its limitations become apparent when it comes to processing, however: unlike metals and plastics, wood can’t be melted and easily reshaped, but has to be sawn, planed or curved. Processes that involve conversion, to make products such as paper, card and textiles, destroy the underlying ultrastructure, or architecture of the wood cells. But the new technology now presented allows wood to be, in effect, grown into exactly the shape desired for the final product, through the medium of 3D printing.

By previously converting wood pulp into a nanocellulose gel, researchers at Chalmers had already succeeded in creating a type of ink that could be 3D printed. Now, they present a major progression, successfully interpreting wood’s genetic code, and digitizing it so that it can instruct a 3D printer.

That means the arrangement of the cellulose nanofibrils can be precisely controlled during the printing process to actually replicate the desirable ultrastructure of wood. Being able to manage the orientation and shape means they can capture natural wood’s useful properties.

“This is a breakthrough in manufacturing technology. It allows us to move beyond the limits of nature, to create new sustainable, green products. It means that those products which today are already forest-based can now be 3D printed, in a much shorter time. And the metals and plastics currently used in 3D printing can be replaced with a renewable, sustainable alternative,” said Professor Paul Gatenholm, who has led this research through the Wallenberg Wood Science Centre at Chalmers.

A further advance is the addition of hemicellulose, a natural component of plant cells, to the nanocellulose gel. The hemicellulose acts as a glue, giving the cellulose sufficient strength to be useful, in a similar manner to the natural process of lignification, through which cell walls are built.

The new technology opens up a whole new area of possibilities. Wood-based products could now be designed and grown to order at a vastly reduced time scale compared with natural wood.

The group has already developed a prototype for an innovative packaging concept. They printed out honeycomb structures, with chambers in between the printed walls, and then managed to encapsulate solid particles inside those chambers. Cellulose has excellent oxygen barrier properties, meaning this could be a promising method for creating airtight packaging for foodstuffs or pharmaceuticals for example.

“Manufacturing products in this way could lead to huge savings in terms of resources and harmful emissions,” he says. “Imagine, for example, if we could start printing packaging locally. It would mean an alternative to today’s industries, with heavy reliance on plastics and C02-generating transport. Packaging could be designed and manufactured to order without any waste”.

They have also developed prototypes for healthcare products and clothing. There’s huge potential for this technology in space. “The source material of plants is fantastically renewable, so the raw materials can be produced on site during longer space travel, or on the moon or on Mars. If you are growing food, there will probably be access to both cellulose and hemicellulose,” said Gatenholm.