Defects can make a material stronger or fail catastrophically. However, knowing how fast they travel helps researchers understand ruptures, structural failures, and precision manufacturing. Recently, scientists discovered that tiny linear defects can propagate through a material faster than sound waves.

These defects, or dislocations, give metals their strength and workability or make materials fail catastrophically—think popping the pull tab on a soda can.

The speed involved provides a new appreciation of the damage they might do to a broad range of materials in extreme conditions—from rock ripped apart by an earthquake rupture to aircraft shielding materials deformed by extreme stress.

Until now, it was impossible to directly measure how fast dislocations spread through materials. The researchers, however, used X-ray radiography to clock the speed of the propagating dislocations through diamond, yielding lessons that should apply to other materials, too. They described the results in Science.

Sound travels faster through solid materials than air or water, depending on the nature and temperature of the material and other factors. The speed of sound through air is 761 mph, but it’s 3,355 mph through water and an incredible 40,000 mph in diamond.

There are two types of sound waves in solids: longitudinal waves and transverse sound waves, which are slower-moving. When dislocations move faster than sound, they behave differently, resulting in unexpected failures. Without measurements, it’s unknown how much damage those ultrafast dislocations do.

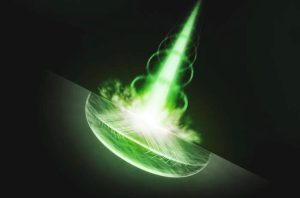

The team used intense laser light to generate shock waves in diamond crystals. Then, they took a series of ultrafast X-ray images of the dislocations forming and spreading on a timescale of billionths of a second. The initial shock wave split into two types of waves. The first wave, called an elastic wave, temporarily deformed the crystal; its atoms immediately bounced back into their original positions. The second plastic wave permanently deformed the crystal by creating small errors in the repeating patterns of atoms that make up the crystal structure.

These dislocations create “stacking faults” where adjacent layers of the crystal shift with respect to each other so they don’t line up the way they should. The stacking faults propagated outward from where the laser hit the diamond, with a moving dislocation at the leading tip of each stacking fault. The researchers discovered that the dislocations spread through the diamond faster than the speed of the slower transverse wave—a phenomenon that had never been seen in any material before.