Fast Burst of Infrared Light Delivers 3D Processing in Semi Chips

Lithography has limitations, particularly given its surface processing nature. The researchers from LP3 Laboratory, France, developed a light-based technique for local material processing anywhere in the 3-D space of semiconductor chips. This technique opens the potential to exploit the sub-surface space for higher integration densities.

The researchers developed new capabilities to fabricate embedded structures inside various semiconductor materials, demonstrating the successful fabrication of Si and GaAs, which cannot be 3-D processed with conventional ultrafast lasers. They published their report in the International Journal of Extreme Manufacturing.

In their research, the wavelength used is infrared, so the semiconductors are a fully transparent material. Within the investigation, they rapidly identified standard telecommunication wavelengths as excellent candidates for 3D processing inside semiconductors. In addition to wavelengths, they also attacked other issues.

CREDIT: BY ANDONG WANG, POL SOPEÑA AND DAVID GROJO

With intense light, as required for material processing, highly efficient nonlinear ionization inside narrow-gap materials creates free electrons inside the material. This rapidly transforms any semiconductor into metal-like materials, deteriorating the focusing process and preventing material modification using ultrafast lasers.

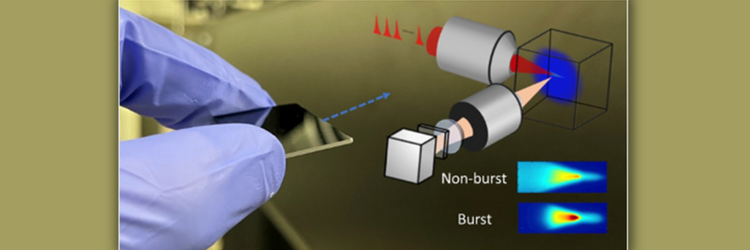

The team used non-conventional ultrafast bursts of pulses to circumvent the metallization transition. Instead of using intense light pulses, they split the pulse energy into several weaker pulses with an extremely fast repetition rate. The bursts avoid strong pulse excitation before the light is focused, and the pulses repeat very fast so that the delivered laser energy can accumulate efficiently to cross the modification.

The researchers claim that the work represents the first practical solution for ultrafast laser writing inside semiconductors.