Harnessing 40% of Sun’s Heat to Produce Clean Hydrogen Fuel

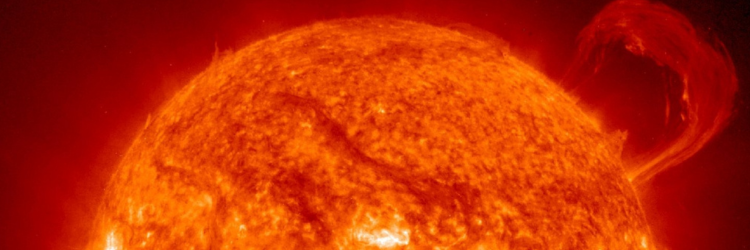

MIT engineers designed a system that can efficiently harness the sun’s heat to split water and generate hydrogen. The goal is to produce green, carbon-free hydrogen fuel with a train-like system of reactors driven solely by the sun.

Their study, published in Solar Energy Journal, describes a system that produces “solar thermochemical hydrogen,” harnessing the sun’s heat to split water and generate hydrogen directly. The fuel could power long-distance trucks, ships, and planes while emitting no greenhouse gas.

Hydrogen production today involves natural gas and other fossil fuels, rendering it a gray energy source. Solar thermochemical hydrogen, or STCH, offers an emissions-free alternative, relying entirely on renewable solar energy to drive hydrogen production. So far, existing STCH designs have limited efficiency, with only 7% of incoming sunlight used to make hydrogen.

MIT estimates its new design could harness up to 40 percent of the sun’s heat to generate that much more hydrogen. The increase in efficiency could drive down the system’s overall cost for an affordable option to help decarbonize the transportation industry.

Similar to other proposed designs, the MIT system would be paired with an existing source of solar heat, such as a concentrated solar plant (CSP) — a circular array of hundreds of mirrors that collect and reflect sunlight to a central receiving tower. An STCH system then absorbs the receiver’s heat and directs it to split water and produce hydrogen. This process is very different from electrolysis, which uses electricity instead of heat to split water.

At the heart of a conceptual STCH system is a two-step thermochemical reaction. In the first step, water in the form of steam is exposed to a metal. This causes the metal to grab oxygen from steam, leaving hydrogen behind. This metal “oxidation” is similar to the rusting of iron in the presence of water, but it occurs much faster. Once hydrogen is separated, the oxidized (or rusted) metal is reheated in a vacuum, which acts to reverse the rusting process and regenerate the metal. With the oxygen removed, the metal can be cooled and exposed to steam again to produce more hydrogen. This process can be repeated hundreds of times.

Challenges included: without recovering and reusing the heat, the system’s efficiency is too low to be practical, and the need to create an energy-efficient vacuum where metal can de-rust.

The MIT system resembles a train of box-shaped reactors running on a circular track. Each reactor would house the metal that undergoes the redox, or reversible rusting, process.

The MIT design incorporates several energy-saving workarounds. The researchers carried out detailed simulations of the conceptual design, finding it would significantly boost the efficiency of solar thermochemical hydrogen production from 7% to 40 percent.

In the next year, the team will be building a prototype of the system that they plan to test in concentrated solar power facilities at laboratories of the Department of Energy, which is currently funding the project.