With the rated range of most electric vehicles at between 200-250 km on a full charge and many newer models capable of more than 400 km these days, electric vehicles are coming into their own. Infrastructure for recharging is lagging and is one of the issues that’s suppressed adoption of EVs.

Extending battery life is a workaround for the infrastructure issue, and researchers at Australia’s Monash University have recently developed the world’s most efficient lithium-sulfur (Li-S) battery and are on the brink of commercializing it. This battery could outperform current market leaders by more than four times.

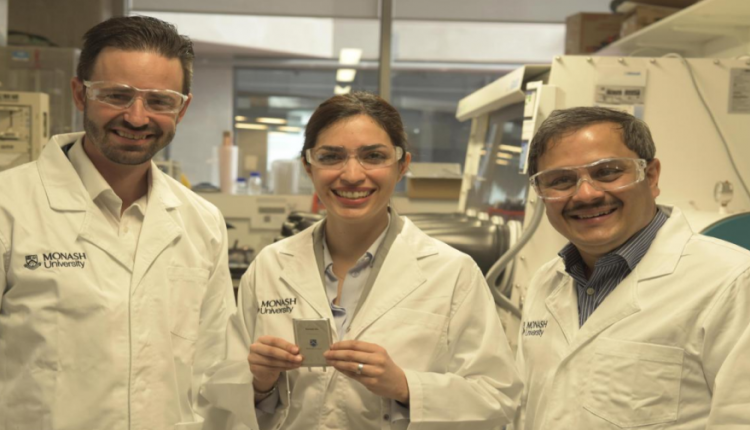

Dr. Mahdokht Shaibani from Monash University’s Department of Mechanical and Aerospace Engineering led an international research team that developed an ultra-high capacity Li-S battery that has better performance and less environmental impact than current lithium-ion products.

The researchers have an approved filed patent (PCT/AU 2019/051239) for their manufacturing process, and prototype cells have been successfully fabricated by German R&D partners Fraunhofer Institute for Material and Beam Technology.

Some of the world’s largest manufacturers of lithium batteries in China and Europe have expressed interest in up-scaling production, with further testing to take place in Australia in early 2020.

Professor Mainak Majumder said this development was a breakthrough for Australian industry and could transform the way phones, cars, computers and solar grids are manufactured in the future.

“Successful fabrication and implementation of Li-S batteries in cars and grids will capture a more significant part of the estimated $213 billion value chain of Australian lithium, and will revolutionize the Australian vehicle market and provide all Australians with a cleaner and more reliable energy market,” Professor Majumder said. “Our research team has received more than $2.5 million in funding from government and international industry partners to trial this battery technology in cars and grids.”

Using the same materials in standard lithium-ion batteries, researchers reconfigured the design of sulfur cathodes so they could accommodate higher stress loads without a drop in overall capacity or performance.

Inspired by unique bridging architecture first recorded in processing detergent powders in the 1970s, the team engineered a method that created bonds between particles to accommodate stress and deliver a level of stability not seen in any battery to date.

Attractive performance, along with lower manufacturing costs, abundant supply of material, ease of processing and reduced environmental footprint make this new battery design attractive for future real-world applications, according to Associate Professor Matthew Hill.

“This approach not only favors high performance metrics and long cycle life, but is also simple and extremely low-cost to manufacture, using water-based processes, and can lead to significant reductions in environmentally hazardous waste,” Associate Professor Hill said.

Source: Monash University