Lowering the Cost of Metal Powders for 3D printing

By Carolyn Mathas

3D printing, creates objects by addition of material, layer by layer and metal powder is typically

used. The powder is produced using atomisation, in which a molten metal stream is broken up

into fine droplets using air or water jets. The technique returns poor yield, is expensive, and is

inflexible in the types of materials it can handle.

In response, researchers at the Indian Institute of Science (IISc) led by Koushik Viswanathan,

Assistant Professor at the Department of Mechanical Engineering, identified an alternative

technique.

In the metal grinding industry, material removed called swarf is often discarded as waste.

Viswanathan’s team showed that these powdery metal bodies form as a result of melting due to

high heat from oxidation at the surface layer. They then refined this process to produce large

quantities of spherical powders, which are collected and processed further to be used as stock

material in AM. The particles perform just as well as commercial gas atomized powders in the

context of metal AM.

Viswanathan points out, but for strategic materials (such as tantalum and lithium), it would be

favorable to have a scalable process for producing metal powders. Then, the entire supply chain

can be housed within a single facility – a possibility their technique could provide.

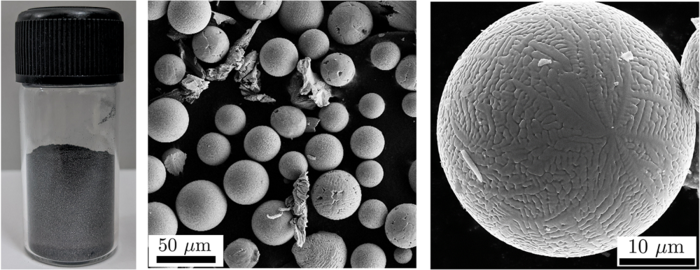

Panel showing metal powders pr [IMAGE] | EurekAlert! Science News Releases