Researchers 3D-print ultrafast graphene supercapacitor electrodes

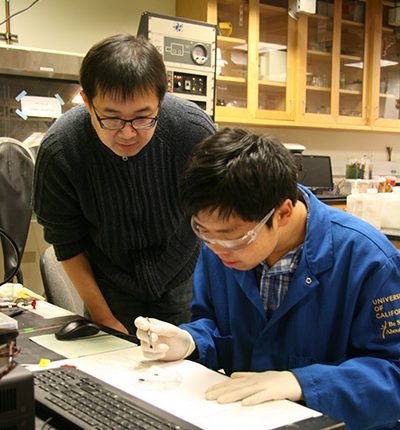

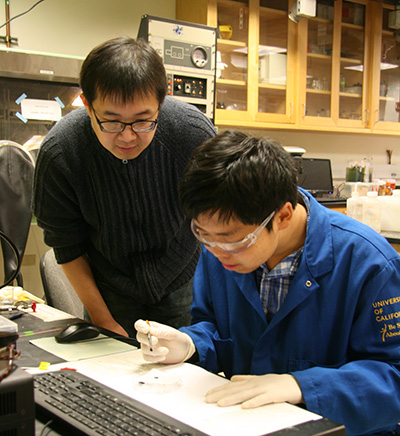

Researcher from the University of California, Santa Cruz, along with the Lawrence Livermore National Laboratory (LLNL) have 3D-printed ultrafast graphene supercapacitor electrodes that have proven to be more efficient than ordinary electrodes. The new electrodes could pave the way for new efficient energy storage systems for smartphones and other electronics like implants, wireless sensors, and electric cars.

To create the new ultrafast graphene supercapacitor electrodes, the team employed a 3D-printing process called direct-ink writing along with a graphene-oxide composite ink.

“Supercapacitor devices using our 3D-printed graphene electrodes with thicknesses on the order of millimeters exhibit outstanding capacitance retention and power densities,” said Yat Li, associate professor of chemistry at UC Santa Cruz. “This performance greatly exceeds the performance of conventional devices with thick electrodes, and it equals or exceeds the performance of reported devices made with electrodes 10 to 100 times thinner.”

According to the researchers, in the future, the newly designed 3D-printed supercapacitors could be used to create unique electronics such as paper or foldable devices that are currently difficult or even impossible to make using other methods. In addition, these devices would be able to achieve levels of performance not yet discovered.

“This breaks through the limitations of what 2D manufacturing can do,” said Cheng Zhu, LLNL engineer. “We can fabricate a large range of 3D architectures. In a phone, for instance, you would only need to leave a small area for energy storage. The geometry can be very complex.”

The devices were made possible with the help of the printable graphene-based ink, but also modification of the 3D printing scheme so that it would be compatible with aerogel processing in order to maintain mechanical and electrical properties of single graphene sheets in the structures. The team was also able to bring the 3D printed supercapacitors to life by using 3D printing to engineer periodic macropores into the graphene electrode to enhance mass transport and allow them to support much faster charge/discharge rates without degrading capacity.

“This work provides an example of how 3D-printed materials such as graphene aerogels can significantly expand the design space for fabricating high-performance and fully integrable energy storage devices optimized for a broad range of applications,” said Li.

Over the next year, the researchers intend to expand the technology by developing new 3D designs, using different inks, and improving the performance of existing materials.

Story via University of California – Santa Cruz

Comments are closed, but trackbacks and pingbacks are open.