Where Are Time of Flight Sensors Used?

Did you know that development of sophisticated devices in the consumer markets and nearly all industrial fields is primarily driven by the development of an assortment of technologies that make machines cognizant of their environment and their roles in those environments?

Technology advancements in 3D imaging are shaping the future of industrial machine vision—making robots that can effortlessly perform tasks a very real, and natural, reality. This reality is due to significant improvement in 3D imaging processes, with 3D technology generally taking on a larger role in machine vision.

Three-dimensional vision technologies significantly help various electronics achieve environmental awareness.

There are four major ways that 3D images are processed:

- Structured light

- Time-of-flight

- Stereo-vision

- Laser triangulation

Time of Flight Sensors

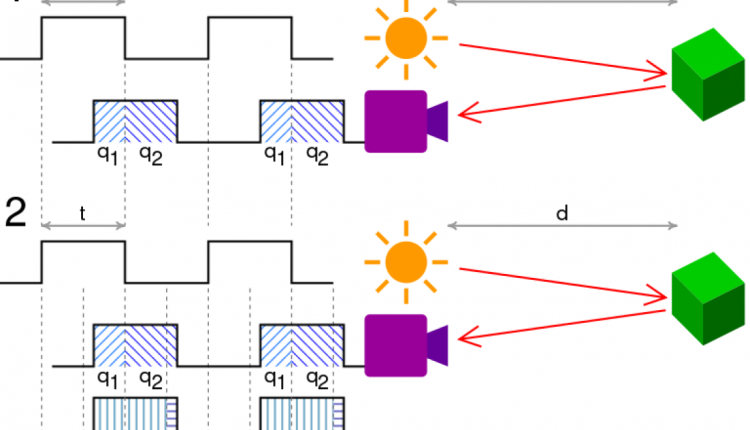

A time of flight sensor (ToF) refers to a range-imaging system that makes use of time-of-flight principles to determine the distance between it and a subject matter. This is done by determining the time taken by an artificial light to travel to and from the subject. In other words, a ToF sensor works by directing light to a scene with the use of a modulated light source, and then gauges phase delay of illumination that return after reflection by objects found in the scene.

ToF sensors are extremely powerful in light emission. As a matter of fact, they are more efficient than ultrasound devices since ToF sensors offer far greater range, better accuracy and superior readings, while maintaining diminutive size, low-power usage and low weight.

ToF Principles

Did you know that the most basic version of the ToF sensor makes use of light pulses or, in some cases, just one light pulse? An operator switches on light for only a few seconds, and pulses automatically light up the scene.

The illumination is also mirrored by any objects lying in the path of view. Reflected light is pulled together by the camera lens and then mirrored onto a focal plane array. Incoming light may be delayed for any number of seconds, and time is determined by distance lying between the two objects. The delay is extremely short, given that light travels at a speed of about 300 million meters within a span of one second.

An object that lies 2.5 meters away from a ToF sensor, for instance, will make light pulses delay by less than 17 ns. For AM rays, maximum range that can be taken care of by a camera depends on the width of the light pulse. For instance, range cannot go beyond 15 meters for a light pulse width of 100 ns. The impressive speeds clearly demonstrate that one of the most important elements of a ToF system is the lighting unit.

Applications of Time of Flight Sensors

- Automotive devices

ToF sensors are commonly used to enhance the safety and support functions of sophisticated automobiles. They play pivotal roles in improvement of active pedestrian safety, OOP detection and other indoor applications as well as pre-crash detection.

- Robotics

The field of robotics has, undoubtedly, embraced widespread use of ToF sensors. Mobile robots, for instance, can quickly create maps of areas they find themselves in enabling consistent obstacle dodging and. The devices make use of minimal computational power since determination of distance is very simple.

- Gaming and human machine boundaries

It can be nearly effortless to track movement of people from one place to another ToF sensors, given that the devices can provide images of distances as things happen. As a result, it has become easier for people to interact with TV sets and other consumer devices. Playing video games has also become more enjoyable, interactive and fascinating, courtesy of ToF sensors.

- Cameras

Developers have come up with sophisticated cameras that make use of ToF sensors. The cameras are used to support research, assorted mobile and web applications, and system integrators in the construction of smart buildings.

- Machine vision and measurement

The devices are commonly used to carry out a variety of measurement tasks. For example, they can play pivotal roles in determining fill height. In many industries, ToF sensors assist in the classification and location of assorted objects that are used by robots. A good example is a case whereby objects pass via a machine through conveyor belts. Today, buildings are even equipped with ToF sensors affixed to doors to help differentiate between people and animals and to prevent unauthorized entry.