When it comes to electronics design, the humble connector plays a big role. It can influence everything from signal integrity to system longevity. Harwin’s 2025 survey of North American engineers and buyers reveals not only how crucial connector selection has become but also offers a data-driven look into the application areas driving demand and the criteria that matter most when choosing a connector supplier.

High-Reliability Leads the Way

One of the key findings from Harwin’s research is the overwhelming emphasis on high-reliability connectors. A full 61% of respondents said they specifically seek out high-reliability components. This preference isn’t just about peace of mind—it’s driven by the increasingly demanding environments in which modern systems operate. One third of respondents said they require reliability lasting between five and ten years, while another third need products that hold up for over a decade.

This focus on long-term performance is reflected in the ranking of key selection criteria. Engineers rated performance, reliability, and operating life as the top three most important factors in their purchasing decisions, outpacing cost, delivery times, or even supplier reputation. These priorities are particularly relevant in markets like aerospace, EVs, and industrial automation, where failure is simply not an option.

A Wide Range of Power and Data Requirements

Connector selection is not one-size-fits-all. The survey revealed a broad spectrum of power needs:

- Low Power (0–30A) was the most common requirement

- Medium Power (30–100A) and High Power (100A+) were also significant

- A notable portion of respondents indicated mixed or unspecified power ranges, suggesting design versatility is often essential

On the data side, the trend skews toward speed:

- Nearly half of respondents reported needing high-speed data support (1 Gbps or higher)

- Mid-range speeds (100 Mbps to 1 Gbps) and low-speed applications still persist, but the shift to high-speed digital systems is clear

Since power and data demands are so diverse, connectors must be versatile, modular, and robust. It also emphasizes why engineers can’t compromise on performance—especially when data integrity and system uptime are on the line.

The Real-World Applications Driving Connector Choices

Connectors are use in so many industries. According to the survey, the top application areas include:

- Industrial & Energy/Utilities – This sector topped the list, driven by demand for rugged, reliable components in automation, energy distribution, and smart grid infrastructure.

- Telecoms & Data Networking – High-speed connectors are essential here for maintaining bandwidth and reducing latency.

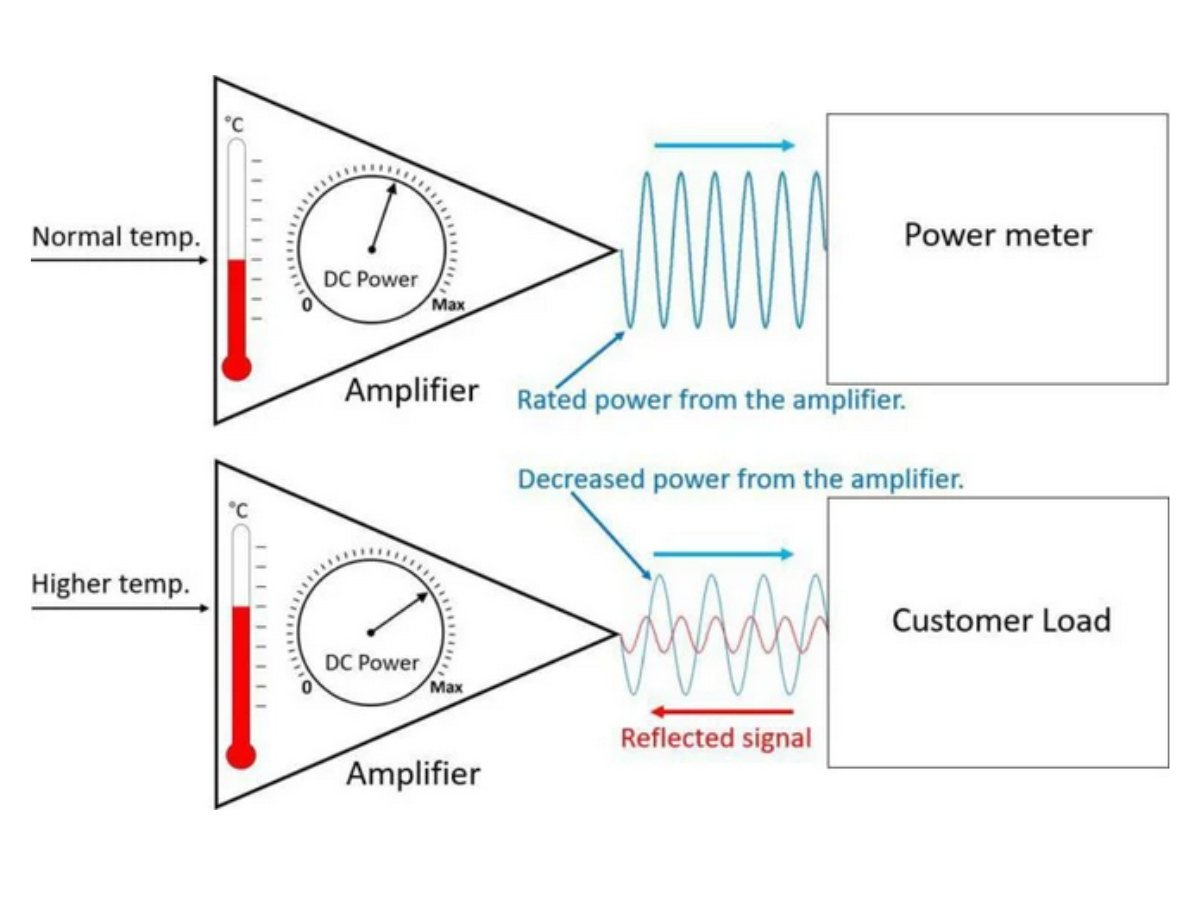

- Automotive & EV – The rise of EVs and autonomous vehicles is fueling demand for compact, heat- and vibration-resistant connectors.

- Aerospace and Space – These sectors require lightweight, high-reliability components that perform in extreme environments.

- Medical Devices – Precision and long life are key, especially for diagnostic and wearable technologies.

- Transportation, Drones, and More – These emerging markets further highlight the diverse and expanding role of connectors.

One common theme among all these sectors is a growing need for miniaturization, ruggedization, and higher data throughput—a trio of pressures that continues to shape connectors.

Beyond Specs: What Engineers Value Most in a Supplier

When evaluating connector suppliers, engineers aren’t just looking at datasheets—they’re evaluating the full support ecosystem. In addition to technical criteria, the survey asked respondents to rate other purchasing priorities. Here’s what stood out:

- Complementary Products (3.84/5) – Engineers prefer suppliers who offer full solutions, not just parts.

- Rapid Sampling (3.81/5) – Speed matters in the prototyping and evaluation stages.

- Cable Assembly & Design Services (3.77/5) – Design support is almost as critical as the product itself.

- Local Technical Support (3.74/5) – Having someone nearby to troubleshoot is highly valued.

- Customization Options (3.67/5) and Global Support (3.61/5) – While slightly lower, these services still weigh into supplier selection.

This indicates a holistic purchasing mindset: product performance opens the door, but strong support and service seal the deal.

Final Thoughts

The results of Harwin’s 2025 survey paint a clear picture: engineers are demanding more from their connectors—and their connector suppliers. Systems are expected to last longer, operate faster, and survive harsher conditions; therefore, connectors are no longer a commodity. They are a strategic component.

High-reliability, robust data and power handling, strong supplier support, and compatibility across diverse application areas are all driving how engineers choose components. For suppliers, the message is equally clear: support the engineer beyond the catalog page. Offer tools, services, and local expertise—and you’ll stand out in a crowded field.

As we move deeper into electrification, automation, and connectivity, connector choice will continue to play a pivotal role in design success. And as this research shows, engineers know exactly what they’re looking for.