There is no doubt that the automotive industry is ‘on the road’ to autonomous driving. As it travels down that highway, the market is investing heavily in Advanced Driver Assistance Systems (ADAS). The focus is twofold: reducing costs and making components smaller. In this quest, Anisotropic Conductive Film (ACF) bonding is becoming a key technology.

Used to make the interconnection between the front-facing camera and the Printed Circuit Board (PCB) that processes the data in high-end cameras for collision warning, Lane Departure Warning System (LDWS), and park-assist applications, ACF bonding solutions are less expensive than other connector options. The ACF technology uses pulsed heat technology with close loop controls to bond ADAS camera interconnections, saving money and contributing to component downsizing.

Rapid movement towards autonomous driving

In the automotive industry, technology available in cars we drive now was typically designed about seven or eight years ago. Current research and development is focusing on a move towards autonomous driving. The market is now investing in ADAS systems for the middle market segment of mainstream cars. This includes collision warning and LDWS applications, as well parking/reversing, night vision, drowsiness monitors, distance warning/autonomous emergency braking, and blind spot detection.

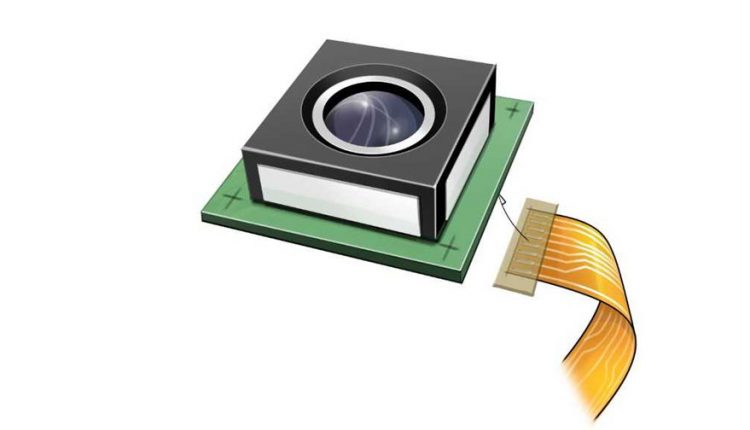

These systems use high resolution cameras with huge amounts of data interpreted by Printed Circuit Boards (PCBs). Designers are seeking to reduce the size of these front-facing windscreen cameras so they are easy to position behind the rear-view mirror, where they will not have an impact on drivers’ and passengers’ view of the road.

In addition to ADAS systems, other electronics systems are being developed to help detect surroundings, interpret information to identify appropriate navigation paths, obstacles, and signage – which will eventually lead to fully autonomous driving. The technology is ready and major automotive companies are starting to implement pieces of it into cars. As production volumes increase and the technology is directed toward mainstream vehicles, manufacturers are looking for ways to reduce costs, downsize interconnections and automate production. The goal is to have full automatic production lines with full process monitoring and no operator involvement.

Technology for connecting cameras to PCBs

ADAS systems require an electrical-mechanical interconnection between the forward-facing camera and the PCB that processes data from the camera. In the past this connection was made with board-to-board connectors or Zero-In-Force (ZIF) connectors, which tend to take up space and add to costs.

An alternative now receiving attention is Anisotropic Conductive Film bonding (ACF bonding), in which parts are joined together with glue that contains conductive particles. The process involves automatic placement of ACF on the PCB or the flex cable. By using accurate parts alignment and applying precise heat, force, and time (in accordance with process parameters), ACF bonding systems make a strong and reliable electrical-mechanical interconnection.

ACF bonding effectiveness relies on having full control of process parameters. With other joining technologies, the average pitch size for many of these applications is about 200 microns, but ACF bonding technology can handle pitches as small as 30 microns. With such small pitches, alignment of parts is critical for ACF applications to work properly – and the alignment should ideally be done automatically. There may be hundreds of electrical connections and each one must make contact with the correct pads. Automotive components must typically operate in demanding conditions to the required automotive specifications and with a wide temperature range – from freezing to 100°C. They may cycle from very cold to very hot, and automotive customers require a high level of connection robustness to ensure a safe design.

It is imperative for the ACF bonding process to accurately control the heat input into the parts. This can be challenge – automotive designers want to make parts as thick as possible, which can make it difficult to bring in the proper amount of heat for a successful ACF bonding process with the proper curing of the glue material. In addition to temperature control, planarity of PCB-flex-tooling will affect the force across the application, which in turn has an effect on the process result.

Benefits of ACF for making interconnections

Cost reduction is the key driver towards using ACF technology for applications requiring PCB and flex cable interconnection with a camera. Typical connectors can be expensive and the ACF interconnection offers a lower cost alternative.

Component downsizing is another potential benefit, because an ACF interconnect is smaller and flatter than a connector. The smaller traditional connectors that would be needed to reduce component size can be much more expensive than ACF bonding.

In addition, ACF facilitates fine-pitch camera interconnection applications as low as 30 microns. If the application requires 100 electrical contacts, the finer the pitch the smaller the flex cable must be. With ACF, more contacts can be placed side by side. The ACF bonding process is ideal for smaller pitches because the particle size is smaller than those of traditional alternatives HSCs. As noted earlier, the ACF process supports a finer pitch – the only challenge to overcome is the alignment of parts.

Another advantage to ACF technology is that it can be used in an automated assembly process. Traditional connectors are designed to be inserted into place in the flex by an operator and then locked into place.

The lead-free and flux-free ACF process is an excellent choice for making electrical-mechanical connections to glass substrates. No cleaning is required after the process and it operates in low process temperatures.

More detailed process and technology information on ACF can be found in a white paper prepared by AMADA MIYACHI EUROPE and in the AMADA MIYACHI EUROPE Technology Library.

Constant heat or pulsed heat technology

ADAS applications that require an interconnection between PCB, flex cable, and camera use ACF technology with one of two options: constant and/or pulsed heat (closed loop controls).

With pulsed heat, one can control the complete temperature/time profile. The bonding process starts at ambient temperature, heats up, maintains the reflow temperature, and then cools down the process tools until a stable ACF connection is established. For example, AMADA MIYACHI EUROPE has developed numerous systems using pulsed heat technology with close loop controls for ACF bonding of ADAS camera interconnections. The UNIFLOW4 power supply used for temperature control provides the targeted heating and precision temperature control necessary. An external MG3 digital weld monitor is used to monitor all process parameters. The MG3 provides precision real-time dynamic measurement of all the welding variables. It offers the tools required for process development, production monitoring, data collection, MES communication and analysis to support ISO, GMP and TQM requirements.

A variety of automotive customers have used these ACF bonding systems for ADAS systems in different parts of production life cycles.

Because AMADA MIYACHI EUROPE also offers laser and resistance welding solutions, it can select the preferred and most effective technology based on specific customer requirements. This is done in a laboratory setting in which application experts define the process and system requirements, prepare samples, and conduct testing and evaluation.