Polymer insulators can be lightweight, flexible, and corrosion-resistant alternatives to traditional metal heat conductors. Applications ranging from heat-dissipating materials in laptops and cellphones, to cooling elements in cars and refrigerators could utilize polymer insulators in the future.

MIT engineers have fabricated thin polymer films that conduct heat better than many metals, including steel and ceramic. The films are thinner than plastic wrap.

Gang Chen’s results were recently published in Nature Communications. The Carl Richard Soderberg Professor of Power Engineering at MI said, “these properties of polymers can create new applications and perhaps new industries, and may replace metals as heat exchangers.”

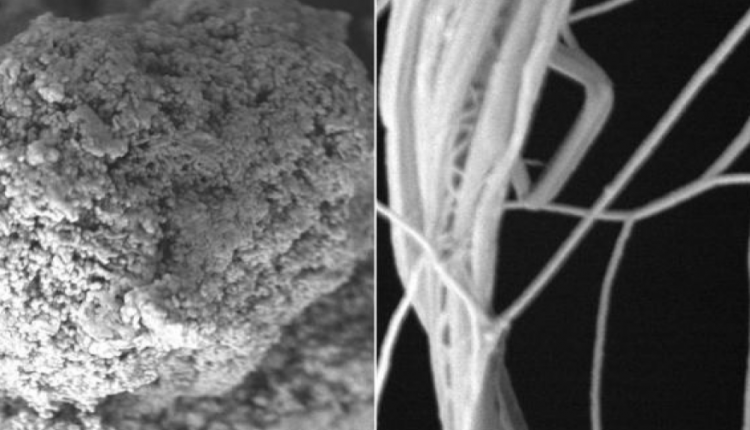

Chen’s team reported success in 2010 fabricating thin fibers of polyethylene that were 300 times more thermally conductive than normal polyethylene, and about as conductive as most metals. Their results, published in Nature Nanotechnology, drew the attention of various industries, including manufacturers of heat exchangers, computer core processors, and even race cars.

It soon became clear the materials would have to be scaled up from ultrathin fibers (a single fiber measured one-hundredth of the diameter of a human hair) to more manageable films. The researchers not only had to come up with a way to fabricate heat-conducting sheets of polymer, but they also had to custom-build an apparatus to test the material’s heat conduction, as well as develop computer codes to analyze images of the material’s microscopic structures.

In the end, the team was able to fabricate thin films of conducting polymer, starting with a commercial polyethylene powder. They dissolved polyethylene powder in a solution that prompted the coiled polymer chains to expand and untangle. A custom-built flow system further untangled the molecular chains, and spit out the solution onto a liquid-nitrogen-cooled plate to form a thick film, which was then placed on a roll-to-roll drawing machine that heated and stretched the film until it was thinner than plastic wrap.

When tested for heat conduction, the new polyethylene film measured around 60 watts per meter per kelvin. (Diamond, the best heat-conducting material, comes in at around 2,000 watts per meter per kelvin, while ceramic measures about 30, and steel, around 15.) As it turns out, the team’s film is two orders of magnitude more thermally conductive than most polymers, and also more conductive than steel and ceramics.

Source: MIT