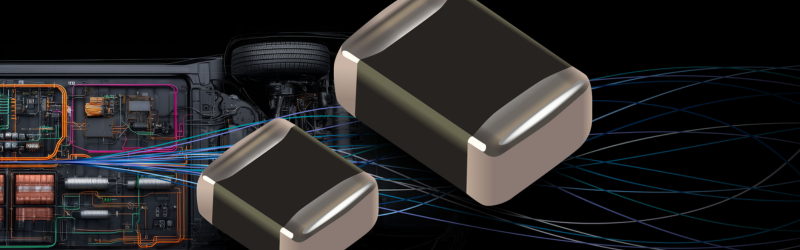

As electric vehicles (EVs) push toward higher performance and longer range, the demands placed on onboard chargers (OBCs) continue to grow. Higher battery voltages require faster charging rates, while design constraints call for smaller, lighter, and more thermally efficient solutions. Meeting these challenges requires rethinking how power conversion is approached at the component level.

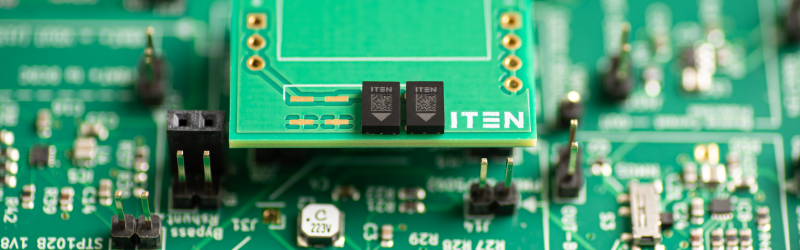

ROHM Semiconductor’s latest development — a series of 4-in-1 and 6-in-1 SiC molded modules in the HSDIP20 package — offers a fresh answer. Designed specifically for power factor correction (PFC) and LLC converter circuits in OBCs and other high-power applications, the new modules promise to significantly improve both power density and thermal management, two critical parameters for modern EV systems.

Tackling the Thermal Barrier in Power Electronics

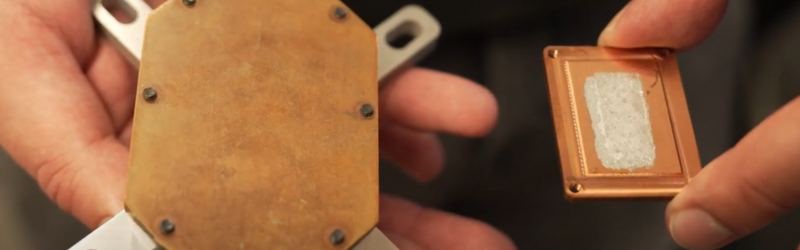

In traditional OBC architectures, discrete SiC MOSFETs with top-side cooling have been the go-to approach. However, as power levels rise, managing heat and maintaining compact form factors becomes increasingly difficult. ROHM’s new HSDIP20 package tackles this head-on by integrating multiple SiC devices into a compact, molded module with an insulating substrate engineered for high thermal conductivity.

In side-by-side comparisons, ROHM demonstrated that a PFC circuit using its 6-in-1 HSDIP20 module ran approximately 38°C cooler than a discrete configuration operating under the same conditions (at 25W operation). The result: a solution that not only supports higher current handling but does so in a smaller, more thermally stable form.

Pushing the Limits of Power Density

Power density — the amount of power handled per unit volume — is a key metric for both designers and manufacturers of EV power systems.

ROHM’s HSDIP20 module delivers:

-

Over 3× the power density of top-side cooled discrete SiC MOSFETs

-

More than 1.4× the density of traditional DIP-type modules

This performance translates into up to 52% less mounting area in OBC circuits, a significant advantage for engineers looking to minimize space and weight without sacrificing efficiency or thermal performance.

Broader Applications Beyond EVs

While onboard chargers for EVs are a primary target, the flexibility of the HSDIP20 platform makes it suitable for a wide range of applications requiring high-efficiency power conversion in tight spaces. Potential use cases include:

-

Automotive systems:

-

Onboard chargers

-

Electric compressors

-

-

Industrial equipment:

-

EV charging stations

-

V2X systems

-

AC servo drives

-

Server power supplies

-

PV inverters and energy storage systems

-

The integrated design approach also simplifies manufacturing, potentially reducing BOM count and assembly complexity for designers across multiple industries.

What’s Next from ROHM

ROHM has signaled that this launch is only the beginning. The company plans to continue evolving its SiC module portfolio, with a particular focus on automotive-grade intelligent power modules (IPMs) that combine high reliability with smaller form factors.

In addition to hardware, ROHM is offering simulation tools, thermal design resources, and evaluation kits that allow engineers to quickly benchmark the new modules under realistic circuit conditions. Support materials include kits for double-pulse testing and 3-phase full-bridge configurations, easing the integration process into next-generation designs.

A Step Toward More Efficient Electrification

As the electrification of vehicles and infrastructure accelerates, breakthroughs in component-level design like ROHM’s HSDIP20 modules are vital. By pushing the limits of heat dissipation and power density, while simplifying system-level design, these innovations help pave the way for smaller, faster, and more efficient EV charging and power conversion systems.

Availability of the new modules has begun for OEM customers as of April 2025.