As modern electronics—especially in automotive, industrial, and consumer applications—become increasingly complex and miniaturized, selecting the right transient protection device is critical. Engineers face more than just component selection—they must balance trade-offs in clamping speed, energy absorption, footprint, and cost.

This article breaks down the key differences between TVS diodes, multilayer varistors (MLVs), and polymer ESD suppressors, using real-world examples from Bourns, Littelfuse, Vishay, and Murata.

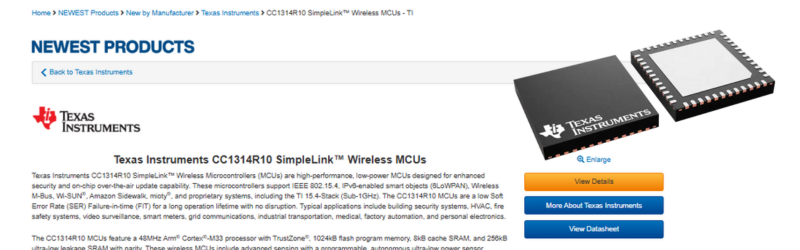

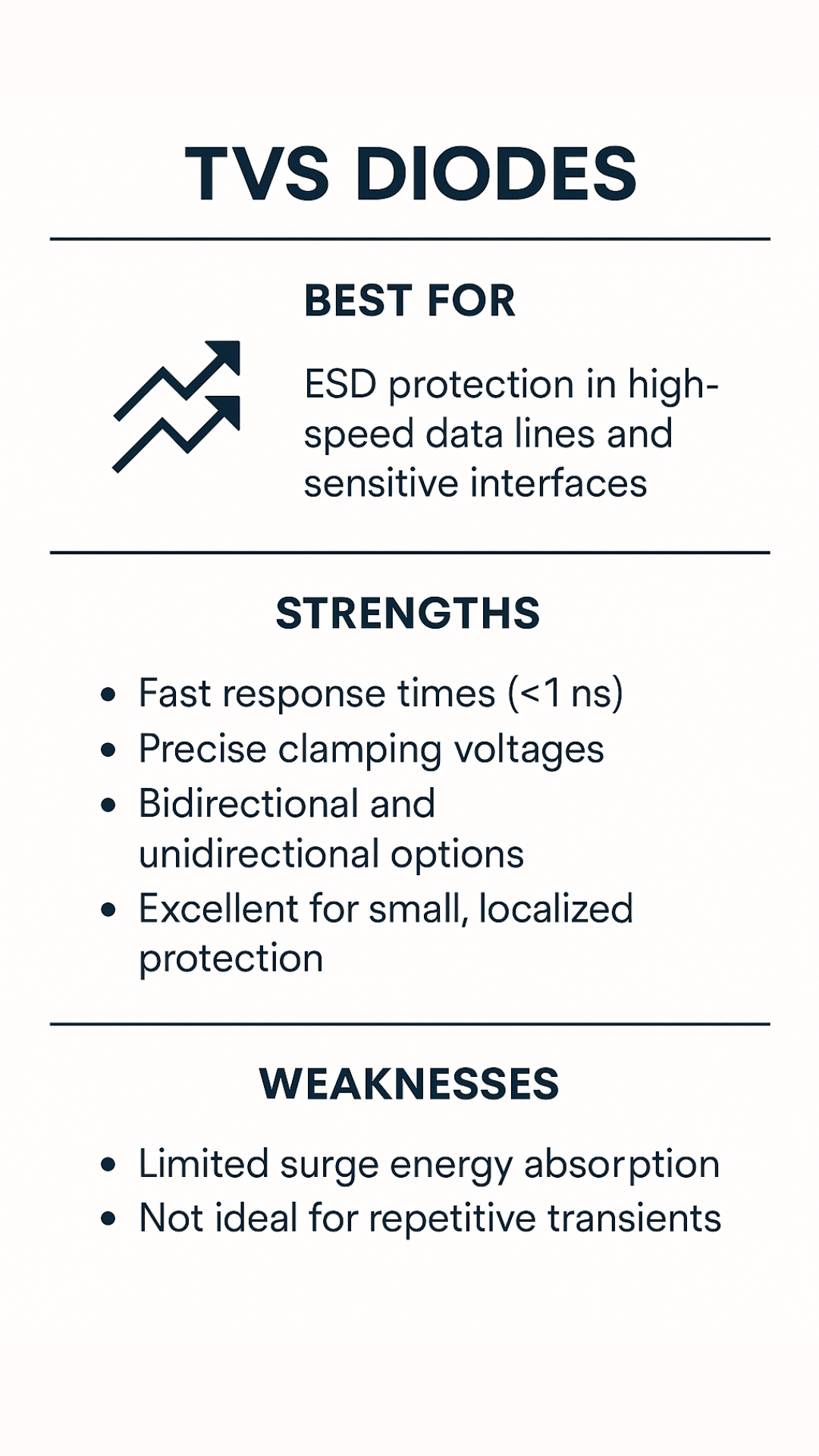

TVS Diodes: Fastest Clamp, Narrow Use Case

Example:

Example:

Littelfuse’s SMAJ series offers robust ESD and EFT protection for automotive and telecom applications. These TVS diodes are often used on CAN, LIN, and USB lines for their ability to clamp surges tightly and quickly.

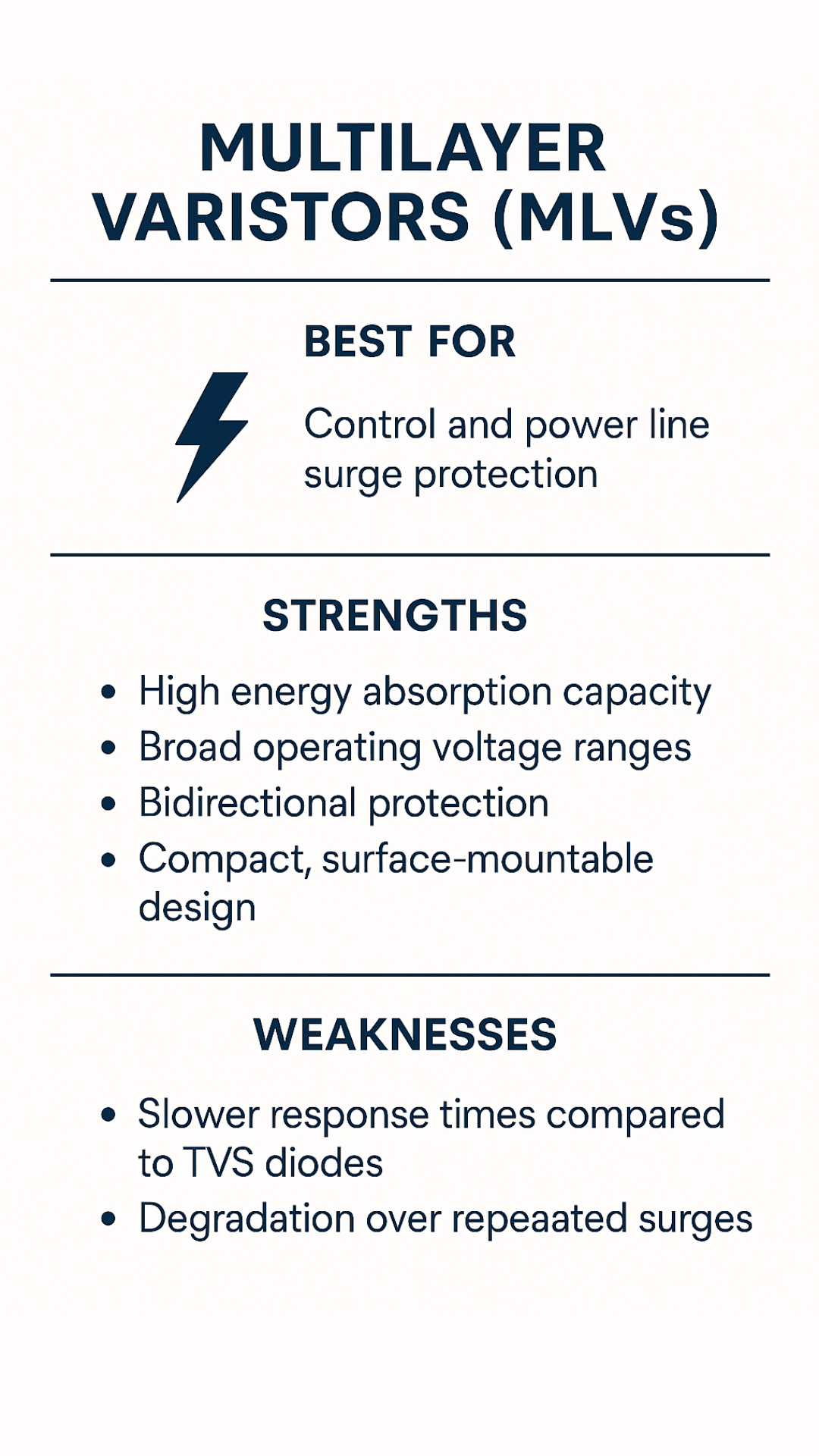

Multilayer Varistors (MLVs): Compact, Repetitive Protection

Example:

Example:

Bourns’ new automotive-grade MLVs, introduced in April 2025, are rated for higher energy absorption while meeting AEC-Q200 standards. Designed for powertrain and infotainment applications, they offer a balance between surge protection and board space efficiency.

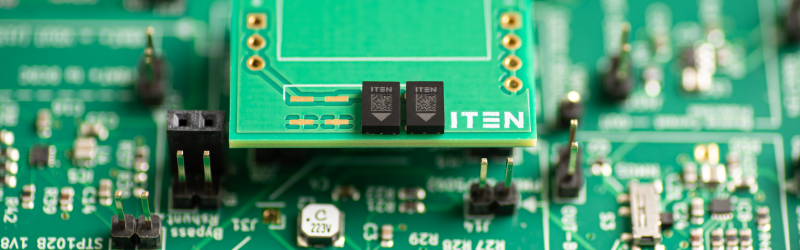

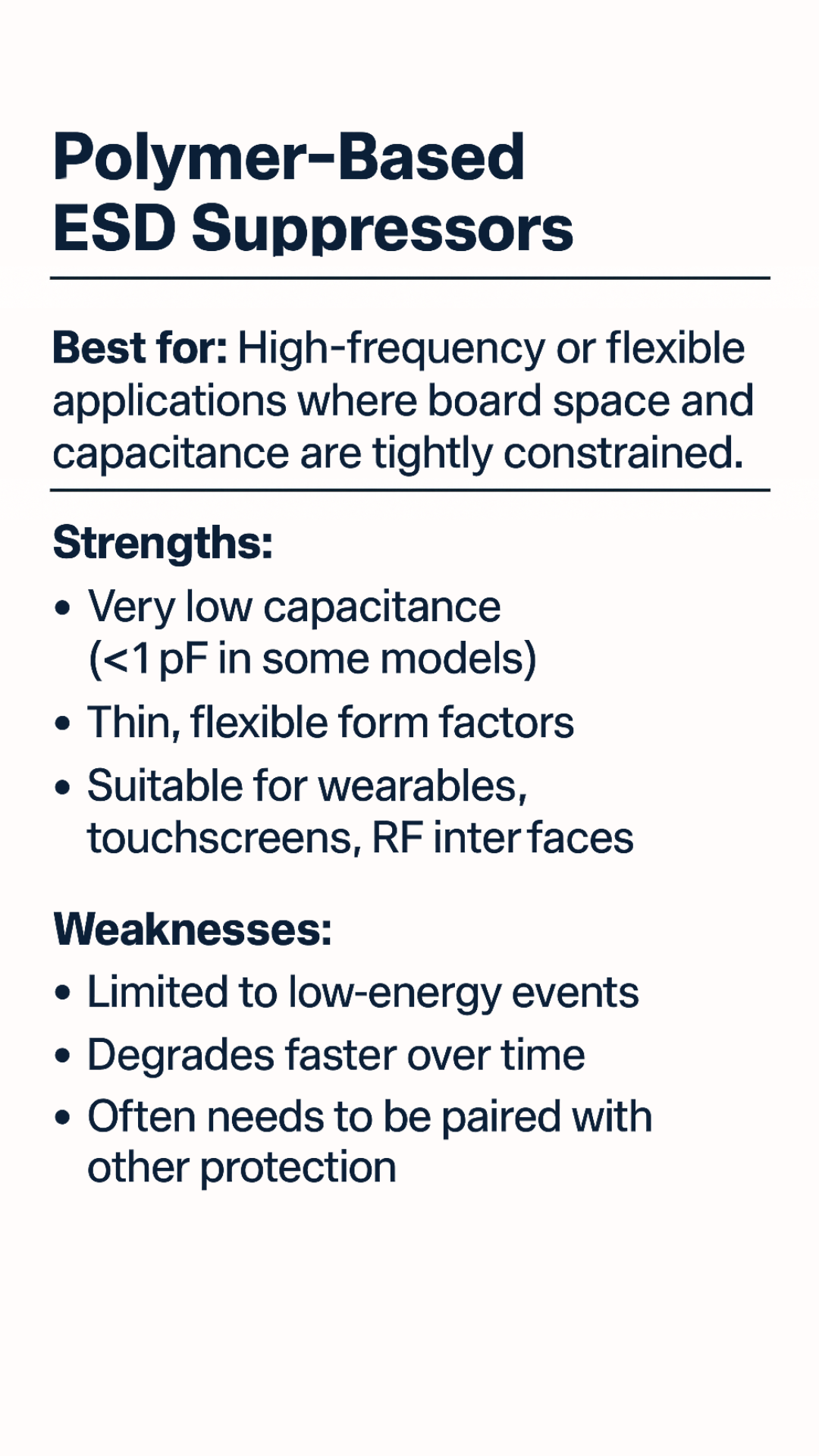

Polymer-Based ESD Suppressors: Flexible, Low-Capacitance

Example:

Example:

Murata’s UX series polymer suppressors are used in smartphones and tablets to protect display and antenna lines without degrading signal quality. Their ultra-low capacitance makes them ideal for maintaining signal integrity in high-speed lines.

Application-Driven Decisions: Getting Protection Where It Matters

While it might be tempting to standardize on a single type of surge protection device, real-world designs almost always require a layered approach. Engineers must consider not just the energy of the transient, but also where and how that transient might enter the system, and which components are most sensitive to it.

-

TVS Diodes are typically deployed on data lines, communication ports, and sensitive IC inputs—anywhere that signal integrity and speed are paramount. For instance, HDMI, USB-C, CAN, and Ethernet lines all benefit from the fast response and tight clamping voltages of a TVS diode.

-

MLVs (Multilayer Varistors) are most effective on power rails and control lines, where repeated surges may occur due to switching inductive loads, load dump scenarios in vehicles, or power line fluctuations in industrial environments. Their robust surge endurance makes them ideal for protecting microcontroller VDD lines or high-side FET gates.

-

Polymer-Based ESD Suppressors shine in capacitive-sensitive and size-constrained environments—especially on wearables, RF interfaces, capacitive touch panels, and antennas. Their low capacitance ensures that high-speed signals pass through unimpeded, while still providing a first line of defense against ESD events from user interaction.

Design Example: In a modern electric vehicle’s infotainment unit:

-

A TVS diode might be used to guard the USB-C charging/data port from ESD or cable-insertion surges.

-

An MLV might sit across the 12V power input to handle surges from the vehicle’s power system during ignition or relay switching.

-

A polymer suppressor could be placed directly on the capacitive touchscreen to prevent ESD damage when users interact with the display in dry environments.

How to Select the Right Device

Selecting the right transient protection device isn’t just about picking one from a datasheet. Engineers need to understand the electrical environment and trade-offs involved. Here are key factors to consider:

-

Clamping Voltage vs. Operating Voltage: Choose a device with a clamping voltage well below the damage threshold of protected components, but above the peak operating voltage.

-

Surge Energy Ratings: Match the device’s surge energy handling to the worst-case transients expected in your application. Automotive environments may see multiple-kilovolt surges, while ESD-only environments may be far less demanding.

-

Capacitance: Critical for high-speed or RF designs. Excess capacitance can attenuate or distort signals. Polymer devices are ideal here; MLVs and some TVS diodes may be too capacitive.

-

Form Factor & Integration: Space is often tight. Some protection devices are available in compact, low-profile packages or can be integrated into connector housings to save board space.

-

Environmental Ratings: Ensure your selection meets AEC-Q200 for automotive, or relevant industrial/military standards, depending on the target application.

Tip: Many component suppliers offer selection tools or simulation models that allow engineers to evaluate real-time current and voltage performance under simulated surge conditions. These tools can prevent overdesign or premature failure.

Build Resilience into the Design

There’s no one-size-fits-all solution to transient protection—nor should there be. Each type of protection device brings unique characteristics that make it optimal in certain roles but suboptimal in others.

Smart design involves balancing:

-

Protection level vs. performance impact

-

Cost vs. reliability

-

Size vs. energy-handling

Keeping up with component advancements—such as Bourns’ high-energy MLVs or Littelfuse’s low-capacitance TVS solutions—helps engineers make informed decisions, especially as systems become smaller, faster, and more interconnected.

As the demand for smarter, more robust electronics grows, understanding how to effectively apply surge protection will remain a fundamental skill for electrical engineers across all industries.