Fujitsu Laboratories develop process to manufacture CNTs

Fujitsu Laboratories announced last week they have developed a process to manufacture sheets of pure carbon, multi-walled perpendicular nanotubes (CNTs). The uniformly arrayed tubes are aligned in the direction of heat removal so that they can be used as heat sinks for a number of electronic applications including silicon carbide devices employed in electric vehicles and in high-performance computing.

Fujitsu says its CNT sheets can dissipate heat at a rate of 80 watts-per-meter Kelvin even with contact resistance included. That is roughly three times the thermal conductance of indium sheets, a material known for its high thermal conductivity, which makes Fujitsu’s technology the world’s top heat-dissipation performer, the company claims.

CNTs’ inherent usefulness as heat-dissipation material has long been known, but exploiting this characteristic in anything other than the simplest of applications has been a headache for material scientists.

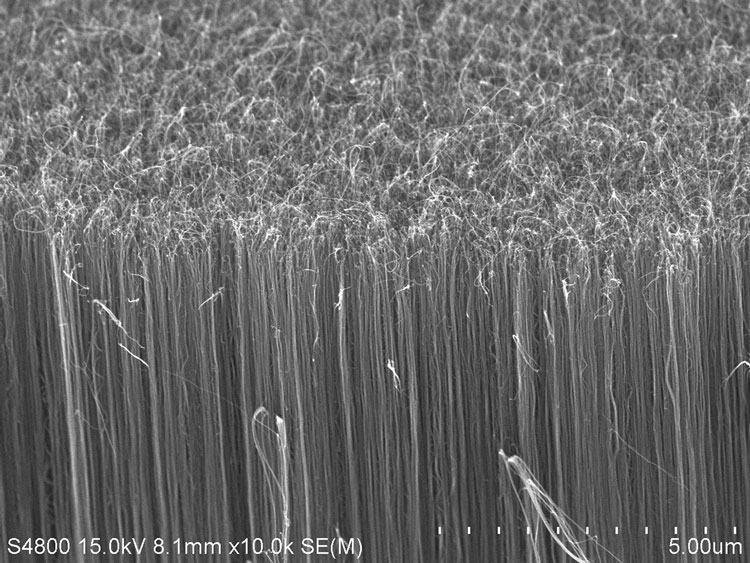

A major problem arises at the manufacturing stage. Chemical Vapor Deposition (CVD) is used to deliver carbon as a gas so that it grows in tube form on metal particles that act like seeds. However, the tubes vary in size and densities depending on differences in particle sizes, the density of the gas, and variations in temperature between particles and across the substrate upon which the particles are placed. This makes its use in sheet form problematic.

According to Daiyu Kondo, research manager at Fujitsu Laboratories’ Devices & Materials Laboratory, the company has devised a process that monitors and precisely controls the temperature and gas pressure in the CVD chamber with respect to the metal-particle catalysts. This results in the growth of uniform multi-walled arrays of perpendicular-orientated carbon nanotubes aligned with the direction of heat removal. The size of the sheets that can be manufactured depends on the size of the substrate used—currently, sheets as large as 200mm can be produced.

In addition, Fujitsu has developed a method in which these carbon nanotube arrays are heat-treated at temperatures of over 2,000°C and then pressurized; this strengthens their array and perpendicular orientations and form. Consequently, the CNT sheets can tolerate temperatures of more than 700°C, compared to indium sheets, which have a melting point of about 160°C.

This treatment, said Kondo, has enabled Fujitsu to overcome a second manufacturing issue where CNTs formed on substrates become unstable and so required a fixing agent like resin. However, such agents have low thermal conductivity, which reduces the thermal conductivity and thermal tolerance of CNTs. Fujitsu’s new heat-treatment method makes it possible to manufacture sheets of pure CNTs with high thermal conductivity and heat tolerance without using any fixing agents.

One challenge Fujitsu will face when it plans to commercialize the technology in 2020 is the material’s high cost compared to conventional heat-sink materials. As well as seeking to improve the manufacturing process to reduce the costs of its CNT sheets, Fujitsu intends to focus on premium markets starting with silicon carbide devices in power modules used in electric and hybrid vehicles to control high-voltage electric power equipment, and which can be required to operate at temperatures of 200°C and above.

“We assume that heat dissipation technology will be necessary in many fields in the future,” said Kondo. “And there may be other possible applications for the material, such as in aviation, that we’re not fully aware of at this stage.”