Lambda Research Corporation Combined TracePro with LUXeXceL to Produce Printed Optics

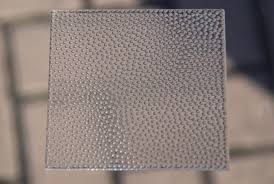

Littleton, MA, USA – Lambda Research Corporation, a leading designer and publisher of the TracePro illumination and optical design software, has collaborated with LUXeXceL to produce customized 3D printed plastic optics. TracePro allows optical designers great versatility to virtually prototype their designs by building textured surfaces to meet the most exacting criteria. After design it is then a simple process to export the texture as a CAD file for LUXeXceL to manufacture. Demonstrating this integrated technology, the companies recently produced a high-quality, commercially-viable lens array using LUXeXceL’s printing technology (see included photograph). Using TracePro Texture optimizer utility a lens array was designed to meet this criteria which diffuses light by using varying texture across the array as well as varying the depths of the features used in the design. TracePro incorporates specific values of LUXeXceL variables and materials, allowing designers to select LUXeXceL materials, which in turn, enables the software to display the light output of a LUXeXceL printed optic. Figure 1 – A custom lens array designed by TracePro and printed by LUXeXceL

“Mass customization of printed optics is now available, providing optical designers with full control over the light distribution, ensuring speed and reduction of project costs,” stated Richard van de Vrie, President & Founder of LUXeXceL. “LUXeXceL’s printing process and TracePro are complementary for optics designers in their quest to design the best solution for every project, not having to compromise with standard, less optimal, products.” Optics designers who make use of TracePro software can modify their projects during the whole development process. In this way, they can immediately check each prototype for optimal output. The LUXeXceL 3D print service is also supportive of an iterative lighting design process. Lenses and custom optics can be printed in days, instead of months. In this way, designers are able to test their optical prototype rapidly and cost-effectively. “TracePro software simulates the distribution of the light and the luminous intensity. This will give designers insight into how the light distribution of their printed product will look like,” explained Michael Gauvin, Vice President of Sales and Marketing at Lambda Research. “The function of our created lens array is to provide randomized uniform light output with light either propagating through the part or reflecting off the part. The texture applied to the part is specific to take a non- uniform propagating light output and create uniform light. This is achieved by varying the texture in such a way that strong light areas are reduced and weak light areas are supplanted by moving light from the strong light areas to the weaker ones”