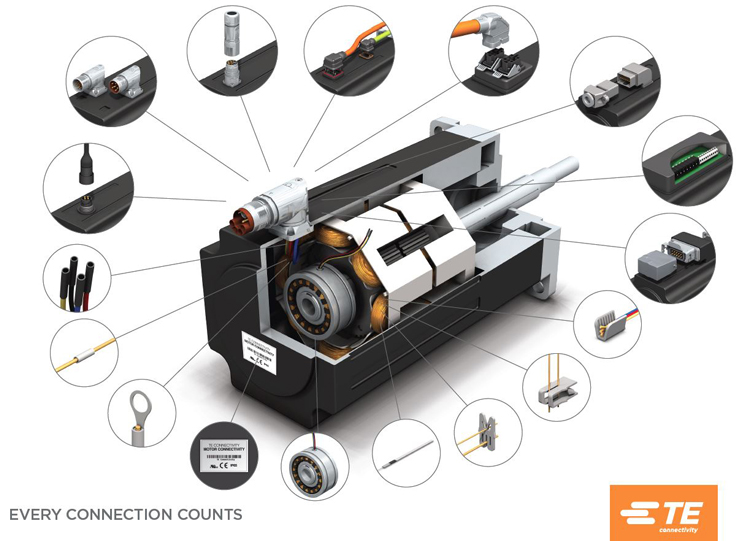

Highly engineered terminals and splices improve energy efficiency

TE Connectivity (TE) provides stepper motor makers and users with one of the broadest portfolios of terminals and splices on the global market. The company works closely together with its customers to develop and supply highly engineered solutions for their requirements. TE’s terminals and splices for stepper motors can be used in applications like robotics, machine tools and pick-and-place machines.

With its decades-long history in development and delivery of terminals, splices and tooling, TE is able to ensure that crimps meet the necessary UL and MIL standards to meet application requirements.

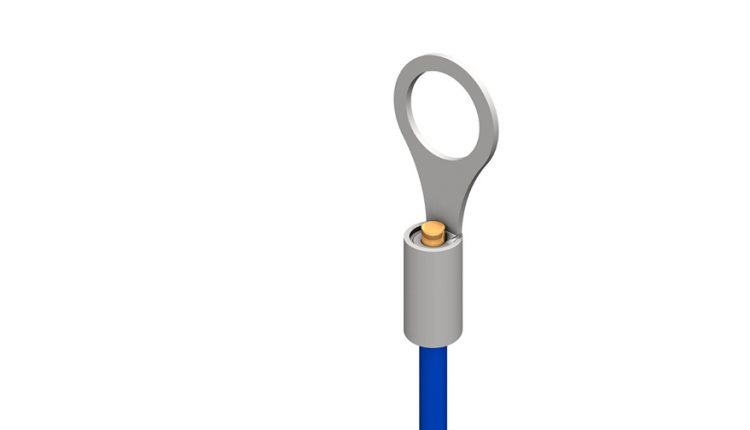

TE helps customers meet and even stay ahead of trends in energy efficiency and precise motion control. The company’s range spans standard products and customization options, available with short lead times and backed up by expert technical service. They offer three distinct families of closed-barrel products: SOLISTRAND, PLASTI-GRIP and PIDG (pre-insulated diamond grip).

SOLISTRAND uninsulated terminals and splices use TE’s ‘W’ crimp. They are for wire sizes from 26AWG to 600MCM and have a voltage rating designed for the recommended wire. SOLISTRAND products are engineered to ensure reliable and long-lasting performance in the most punishing environments.

PLASTI-GRIP insulated terminals and splices use TE’s ‘C’ crimp, are for wires in the 22 to 2/0AWG range and have a 600V rating. These products answer the need for inexpensive insulated electrical terminations.

PIDG types are also insulated and use the ‘C’ crimp, but include metallic sleeves for additional wire insulation support. They are designed for complete and uniform reliability in high vibration environments. Intended for wires in the 26 to 10AWG range, they have a voltage rating of 300V.