Researchers use off-the-shelf 3D printers to create hearts and other organs

While organ transplants are a vital medical option for patients today, there are currently over 4,000 Americans waiting to receive a heart transplant right now.

Researchers have been working with 3D printers to change the way organs are repaired or replaced, so that patients do not have to wait on these lists while their hearts or other organs fail.

A group of researchers from Carnegie Mellon has brought us one step closer, with a new method for 3D bioprinting that could could lead to a world where transplants are no longer necessary.

“We’ve been able to take MRI images of coronary arteries and 3D images of embryonic hearts and 3D bioprint them with unprecedented resolution and quality out of very soft materials like collagens, alginates and fibrins,” said Adam Feinberg, an associate professor of Materials Science and Engineering and Biomedical Engineering at Carnegie Mellon University.

CMU researchers are working to grow 3-D bioprinting into an important tool for a large number of medical applications.

The problem with 3D bioprinting is the texture of the materials. Traditional 3D printers build hard objects made of plastic or metal, and they work by depositing material onto a surface layer-by-layer to create the 3D object. Printing with soft materials like gels has been limited since they collapse under their own weight when 3D printed in air

“3D printing of various materials has been a common trend in tissue engineering in the last decade, but until now, no one had developed a method for assembling common tissue engineering gels like collagen or fibrin,” said TJ Hinton, a graduate student in biomedical engineering at Carnegie Mellon and lead author of the study.

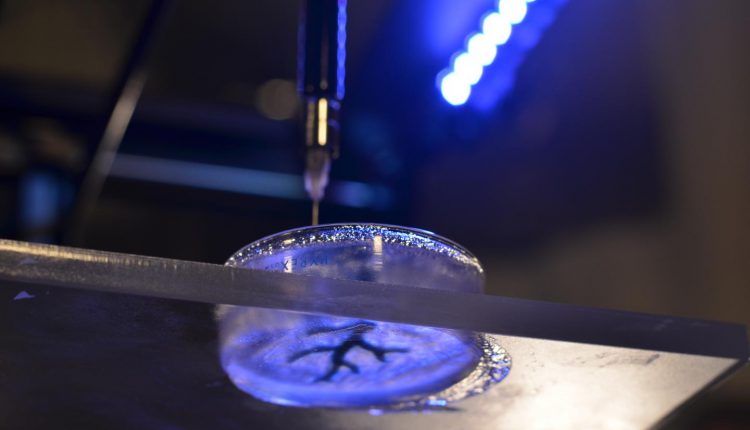

What the researchers did was develop a method of printing these soft materials inside a support bath material.

“Essentially, we print one gel inside of another gel, which allows us to accurately position the soft material as it’s being printed, layer-by-layer,” said Feinberg.

One of the major advances of this technique, termed FRESH, or “Freeform Reversible Embedding of Suspended Hydrogels,” is that the support gel can be easily melted away and removed by heating to body temperature, which does not damage the delicate biological molecules or living cells that were bioprinted.

The researchers will now work toward incorporating real heart cells into these 3D printed tissue structures as a step toward a fully functional muscle.

Bioprinting has been worked on for a few years now, but most 3D bioprinters cost over $100,000 and may require specialized expertise to operate which has limited the technology. Feinberg’s group, however, has been able to implement their technique on a range of consumer-level 3D printers, which cost less than $1,000 by utilizing open-source hardware and software.

“Not only is the cost low, but by using open-source software, we have access to fine-tune the print parameters, optimize what we’re doing and maximize the quality of what we’re printing,” said Feinberg. “It has really enabled us to accelerate development of new materials and innovate in this space. And we are also contributing back by releasing our 3D printer designs under an open-source license.”

Comments are closed, but trackbacks and pingbacks are open.