Thin Insulators for Thin Computer Chips

As we reach peak Moore’s Law, the number of transistors per chip and the number of chips per electronic device has grown exponentially, which means making them smaller. For a long time, something important has been neglected in electronics: If you want to make electronic components smaller and smaller, you also need the right insulator materials.

Ever smaller and ever more compact — this is the direction in which computer chips are developing, driven by industry. This is why so-called 2D materials are considered to be the great hope: they are as thin as a material can possibly be, in extreme cases they consist of only one single layer of atoms. This makes it possible to produce novel electronic components with tiny dimensions, high speed and optimal efficiency.

However, there is one problem: electronic components always consist of more than one material. 2D materials can only be used effectively if they can be combined with suitable material systems — such as special insulating crystals. If this is not considered, the advantage that 2D materials are supposed to offer is nullified. A team from the Faculty of Electrical Engineering at the TU Wien (Vienna) is now presenting these findings in the journal Nature Communications.

Reaching the End of the Line on the Atomic Scale

“The semiconductor industry today uses silicon and silicon oxide,” says Prof. Tibor Grasser from the Institute of Microelectronics at the TU Wien. “These are materials with very good electronic properties. For a long time, ever thinner layers of these materials were used to miniaturize electronic components. This worked well for a long time — but at some point we reach a natural limit”.

When the silicon layer is only a few nanometers thick, so that it only consists of a few atomic layers, then the electronic properties of the material deteriorate very significantly. “The surface of a material behaves differently from the bulk of the material — and if the entire object is practically only made up of surfaces and no longer has a bulk at all, it can have completely different material properties.”

Therefore, one has to switch to other materials in order to create ultra-thin electronic components. And this is where the so-called 2D materials come into play: they combine excellent electronic properties with minimal thickness.

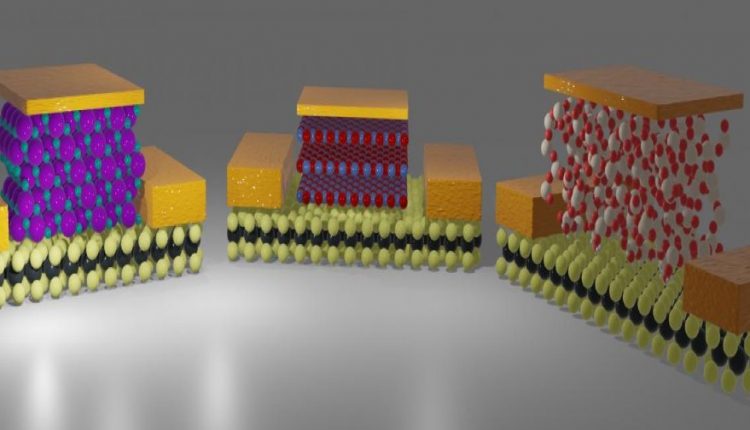

“As it turns out, however, these 2D materials are only the first half of the story,” says Tibor Grasser. “The materials have to be placed on the appropriate substrate, and an insulator layer is also needed on top of it — and this insulator also has to be extremely thin and of extremely good quality, otherwise you have gained nothing from the 2D materials. It’s like driving a Ferrari on muddy ground and wondering why you don’t set a speed record.”

A team at the TU Wien around Tibor Grasser and Yury Illarionov has therefore analyzed how to solve this problem. “Silicon dioxide, which is normally used in industry as an insulator, is not suitable in this case,” says Tibor Grasser. “It has a very disordered surface and many free, unsaturated bonds that interfere with the electronic properties in the 2D material.”

It is better to look for a well-ordered structure: The team has already achieved excellent results with special crystals containing fluorine atoms. A transistor prototype with a calcium fluoride insulator has already provided convincing data, and other materials are still being analyzed.

“New 2D materials are currently being discovered. That’s nice, but with our results we want to show that this alone is not enough,” says Tibor Grasser. “These new electrically conductive 2D materials must also be combined with new types of insulators. Only then can we really succeed in producing a new generation of efficient and powerful electronic components in miniature format.”

Source: Vienna University of Technology