Programmable structures from 3D printing

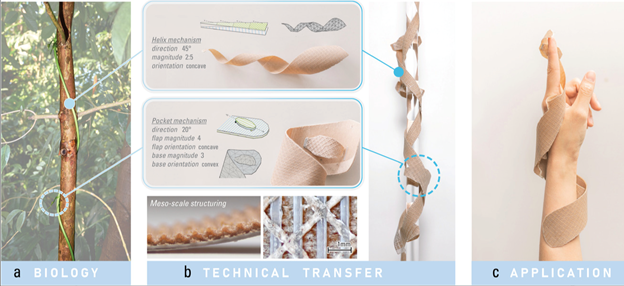

Researchers at the University of Freiburg and the University of Stuttgart have developed a new process for producing movable, self-adjusting materials systems with standard 3D-printers. The systems can undergo complex shape changes, contracting and expanding under the influence of moisture in a pre-programmed way. The movement mechanisms of the climbing plant are akin to the air potato. Based on the new method, the team produced its first prototype—a forearm brace that adapts to the wearer potentially for medical applications.

3D-printing is a widely accepted manufacturing process for a range of applications including intelligent materials and material systems that remain in motion after printing that autonomously change shape from external stimuli such as light, temperature or moisture. The so-called ‘4D-printing’, in which a shape change can be triggered by a stimulus, immensely expands the potential applications of material systems. Printers and base materials used to produce the materials systems are usually highly specialized, custom-made and expensive.

Now, however, it is possible to produce materials systems that react to changes in moisture and that undergo shape changes in the entire system or simply in the individual parts. Scientists used the air potato climbs that climbs trees by applying pressure to the trunk of the host plant. To imitate the mechanisms involved, they used a modular material system, structuring its layers so that it can bend in different directions and to different degrees, thereby coiling and forming a helix structure. ‘Pockets’ on the surface cause the helix to be pushed outwards and put under tension, causing the entire material system to contract.

The process is limited to existing base materials that respond to moisture, however they are hoping that inexpensive materials that respond to other stimuli will become available for 3D-printing and used with the same process.

See Tiffany Cheng, Marc Thielen, Simon Poppinga, Yasaman Tahouni, Dylan Wood, Thorsten Steinberg, Achim Menges, Thomas Speck. Bio‐Inspired Motion Mechanisms: Computational Design and Material Programming of Self‐Adjusting 4D‐Printed Wearable Systems. Advanced Science, 2021; 8 (13): 2100411 DOI: 10.1002/advs.202100411 for more information.

Original Release: Science Daily